We’re touring several U.S.-based battery manufacturing and recycling stars who help form the strong network of BCI member companies. They provide batteries and the services and supplies that are used to create those batteries. They also comprise the vast domestic infrastructure that ensures a reliable energy storage source exists to power the U.S. economy.

Headquartered in Horsham, Pa., C&D Technologies and Trojan Battery Company have more than 200 combined years of operating history. The firm, C&D Trojan (CDT), is a leading global manufacturer of high-performance batteries used in golf/LSEV, data centers, material handling, and other specialized applications.

Its 3,000 employees operate from seven global locations, including four ISO 9001:2015-certified manufacturing plants and two advanced R&D centers. The company also has international sales and support offices in the Americas, Europe, Africa, Middle East, and Asia.

A broad power solutions portfolio

CDT provides a broad power solutions portfolio backed by global support to meet specific needs quickly and efficiently across a wide range of applications. This diverse footprint helps customers rely on a single trusted source for all their energy storage needs.

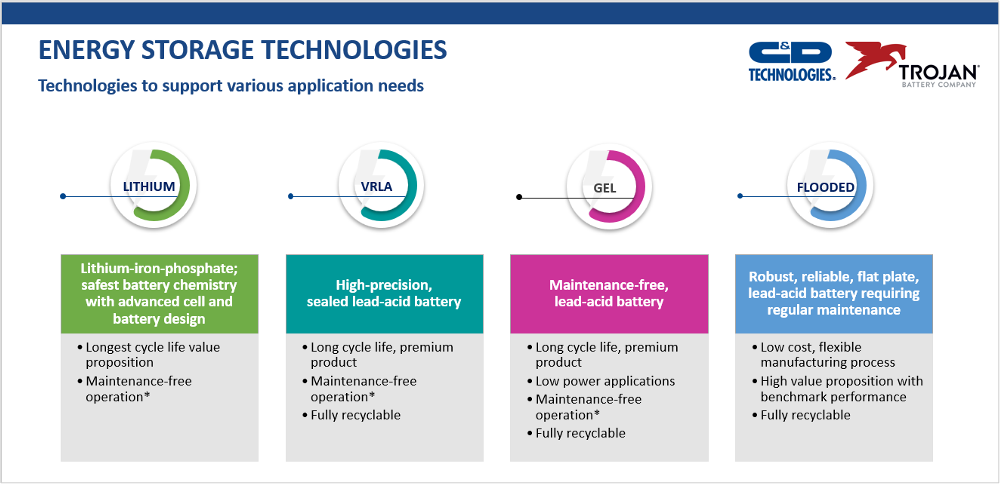

The C&D Technologies arm provides high-quality, safe, reliable, and cost-effective valve-regulated lead-acid (VRLA) and flooded lead-acid batteries. These products and services support data centers, telecommunications, energy, infrastructure, and renewable energy markets.

The Trojan Battery arm has its own complete line of batteries, including lithium-ion, AGM, and flooded lead battery solutions. It is a manufacturer of batteries used in golf carts, personal transportation, and utility vehicles, as well as marine equipment, floor-cleaning machines, aerial work platforms, and material-handling equipment.

“We have one of the most comprehensive power solution portfolios in the industry. The benefit to our customers is that we take a technology agnostic approach that focuses on their specific applications and subsequent energy needs, as opposed to concentrating on certain battery technology,” said Rick Heller, President and CEO of CDT. “Couple this with our 200 years of combined experience; customers have confidence that our solutions and support will meet their needs today and in the future.”

Global leadership and growth

CDT continues to experience consistent growth, with more than 5 million batteries sold worldwide annually. Maintaining global leadership requires forging solid relationships that will support the company’s commitment to innovation and technology advancement.

As part of that commitment, CDT is a proud member of BCI and the Advanced Lead Acid Battery Consortium. A recent example of how those affiliations enhance the battery market is CDT’s participation in the Consortium for Lead Battery Leadership in Long Duration Energy Storage (LDES) established by BCI.

The newly-formed group, funded by the U.S. Department of Energy (DOE), brings together BCI, Consortium for Battery Innovation (CBI), select U.S. lead battery manufacturers, and three national laboratories to conduct pre-competitive research aimed at improving lead battery performance. The goal is to develop lead batteries capable of 10+ hours of storage with a pathway to $0.05/kWh Levelized Cost of Storage by 2030.

“Equally important to meeting the market needs is having strong alignment with OEM partners. Our collaborations with them lead to a laser-focused understanding of the necessary power solutions,” said Heller.

CDT has relationships with OEMs in key markets, including golf carts/utility vehicles, cleaning equipment, and material handling. The battery leader is aligned with Club Car, Taylor-Dunn, and TexTron, among others.

Commitment to sustainability and safety

As part of its commitment to sustainability, CDT has set a clear roadmap to make a positive impact on both people and the planet. The company has established a baseline in 2021 to monitor and improve its environmental performance, with each product’s impact on the earth being measured, quantified, and tracked for compliance. Furthermore, CDT has implemented processes to minimize waste in landfills and reduce water usage, demonstrating its dedication to reducing its environmental footprint.

Carbon emissions per facility have been lowered for three consecutive years. In 2023, the carbon dioxide equivalent reduction per unit produced was 10.9%, and the company is on pace to achieve its 2024 goal of 2.5% reduction in CO2e emissions.

Last year, CDT recycled more than 105M lbs. of spent lead acid batteries and more than 3.8M lbs. of plastic from spent batteries. In addition, 77M lbs. of recycled lead was used to manufacture new batteries.

“Every day, we help customers move to a more sustainable energy storage solution. CDT implements a closed-loop lifecycle. The philosophy results in 99% of our lead-acid batteries being recyclable. We use up to 80% reclaimed materials to produce lead-acid batteries, as well,” said Fred Ganster, VP of Environmental Health & Safety.

At CDT, the health and safety of employees is also a top priority. The company strictly adheres to Job Safety Analysis (JSA) protocols to establish the safest methods of performing tasks, resulting in a recordable incident rate at its facilities that is less than half the U.S. Department of Labor and industry standard established by BCI. CDT also monitors employees’ blood lead average levels to ensure they meet the strict safety standards of all BCI members, which are more restrictive than the current federal requirements.

Creating a safe and healthy work environment is an ongoing process. For that reason, CDT implements a learning management system and conducts regular work instruction and ongoing development training. Compliance and Code of Conduct training is mandatory for all employees so they have a clear understanding of procedures. CDT even begins cross-functional meetings with a “safety tip” to maintain a culture of safety throughout the organization.

Giving back to communities

Being a leader is more than developing innovations and providing the market with solutions that address needs. It also requires companies to be involved in their communities and support causes to benefit others.

For example, the CDT sponsor team walks to raise money for research during Breast Cancer Awareness Month. For years, CDT has conducted a Tech Week to support the PV Power Packs program, a local volunteer-run organization that provides summer pantries and weekend bags of nonperishable food for children and families facing food insecurity. In late 2024, CDT also helped with relief efforts for employees and customers recovering from Hurricane Helene.

Employee teams also gather for collaboration and to build camaraderie. At a recent cross-functional team meeting, a team-building event was held. Employees from various departments gathered to construct boats from cardboard and duct tape with the goal of creating a water-resistant vessel that would float, requiring teamwork, engineering, and ingenuity.

Company-sponsored family picnics are also hosted across the facilities. These events create a family atmosphere and contribute to long-tenured employees—many of whom have been with CDT for 20+ years.

Thank you, C&D Trojan, for the opportunity to get to know you better!

Watch this space for other tour stops, as we travel the country sharing details about an industry that provides billions in domestic economic output and supports more than 121,000 U.S. jobs. Until then, read our previous Essential Energy Tour stops at Hammond Group, Inc., Crown Battery, Gopher Resource, East Penn Manufacturing, ENTEK International, EnerSys and Stryten Energy.