We’re virtually touring several U.S.-based manufacturing stars who help form the strong network of BCI member companies. They provide batteries and the services and supplies that are used to create those batteries. They also comprise the vast domestic infrastructure that ensures a reliable energy source exists to power the U.S. economy.

Commitment to Renewables Makes Ohio-Based Company Sustainability Leader

Crown Battery Manufacturing Company is proving that it’s possible for a nearly 100-year-old company to not only stay relevant, but be at the forefront of innovation and sustainability.

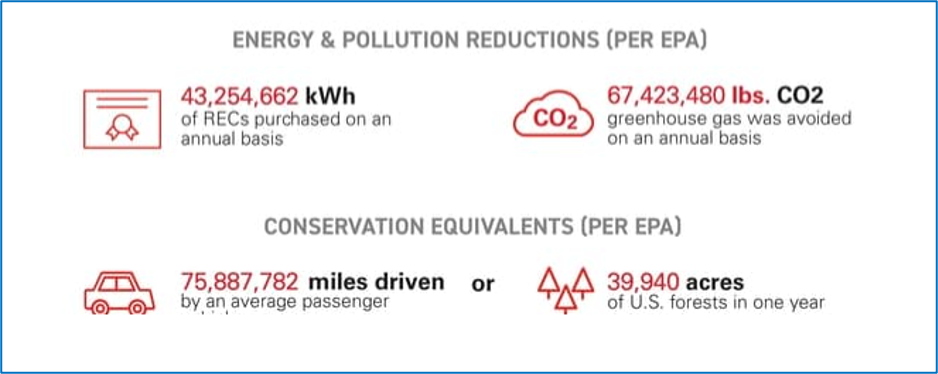

For example, the company has made the green battery chemistry of lead batteries even greener through responsible, renewable manufacturing. In 2020, Crown Battery switched to 100% solar and wind energy for manufacturing, and in 2021 became the first U.S. battery company to completely power its manufacturing using 100% renewable energy – and the first battery company recognized as an EPA Green Power Partner.

Hal Hawk, CEO of Crown Battery, said the across-the-board benefits of sustainability drove the company’s progressive transition.

“Sustainable energy management is the future. Renewable energy is a win-win for our environment, our company, our community, and our customers.”

A Domestic and Global Economic Footprint

From its headquarters in Fremont, Ohio, where its lead battery manufacturing occurs, Crown Battery has become a cornerstone of America’s lead battery energy storage industry. The privately owned and managed company has nearly a century of expertise, innovation and growth in the global energy storage industry.

Today, Crown Battery provides OEM-quality, Made-in-USA lead batteries throughout the Americas and in over 50 countries around the world. It has vast economic impact:

- Five factory distribution facilities in Ohio

- 14 sales and distribution offices in North America

- Over 600 employees

- A network of authorized business partners, distributors and dealers in North America, South America, Europe, Africa, Asia-Pacific, Australia and New Zealand

Providing Essential Power to Millions

Hawk said the company’s operating principle – “The Power Behind Performance” – represents its commitment to providing power to millions of people worldwide.

“We are an essential industry that is key to solving our nation and world’s dramatically growing need for sustainable energy storage,” Hawk said.

The company’s lead battery products support critical lead battery applications in automotive, commercial and industrial sectors:

- Railroad industries

- Underground mining equipment

- Material handling systems

- Renewable energy installation and renewable energy storage

- Recreational marine and automotive industries

- Aerial access equipment

- Floor care and lift truck equipment

Making the World’s Most Recyclable Batteries Greener with Renewable Manufacturing

Lead batteries are already a model of resiliency, reliability and sustainability. In fact, they are considered the most sustainable battery chemistry available.

According to the EPA, lead batteries are the most recycled consumer product in North America, with a 99% U.S. recycling rate. That’s made possible, in large part, by an established North American network to manufacture, collect, recycle and remanufacture lead batteries. This circular economy means approximately 80% of the material for new lead batteries comes from previously recycled lead batteries.

Crown Battery’s proactive approach to sustainable manufacturing takes that “green” to a new level. The company’s investment in renewable energy not only reduces its carbon footprint, it demonstrates how large-scale energy consumers, like manufacturing companies, can innovate and realize the full potential of energy efficiency in their operations.

Culminating its 20-year initiative to using 100% solar and wind energy for manufacturing, the company (from May 2012–June 2021), saved more than 56 million kWh of electricity, or enough to power more than 5,100 homes.

Crown Battery Sets Broad Sustainability Benchmarks

The company has established a number of additional sustainability benchmarks that redefine what makes a battery – and its manufacturer – highly sustainable. Here are highlights, in part, from Crown Battery’s “Walking the Green Walk” Sustainability Fact Book:

- Energy Efficiency The company has invested over $8 million to improve energy efficiency, including the use of on-site solar panels, ultra-efficient lighting, and geothermal cooling. The company also recycles water onsite, which saves more than half a million gallons of water per year.

+ A 51% reduction in treated water discharged from 2016 to 2020.

+ 99.97% air and water filtration – cleaner when they leave the plant than when they come in.

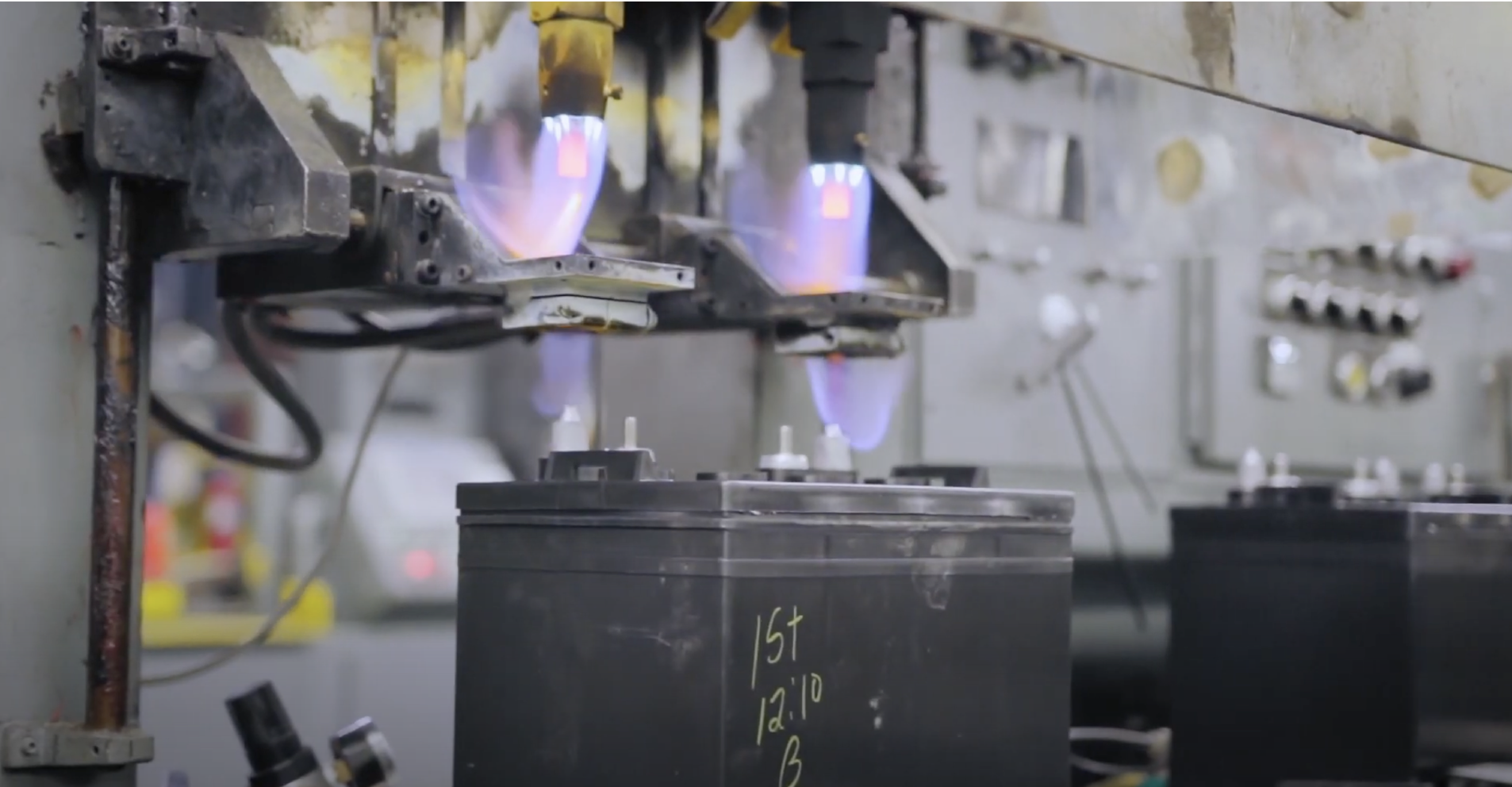

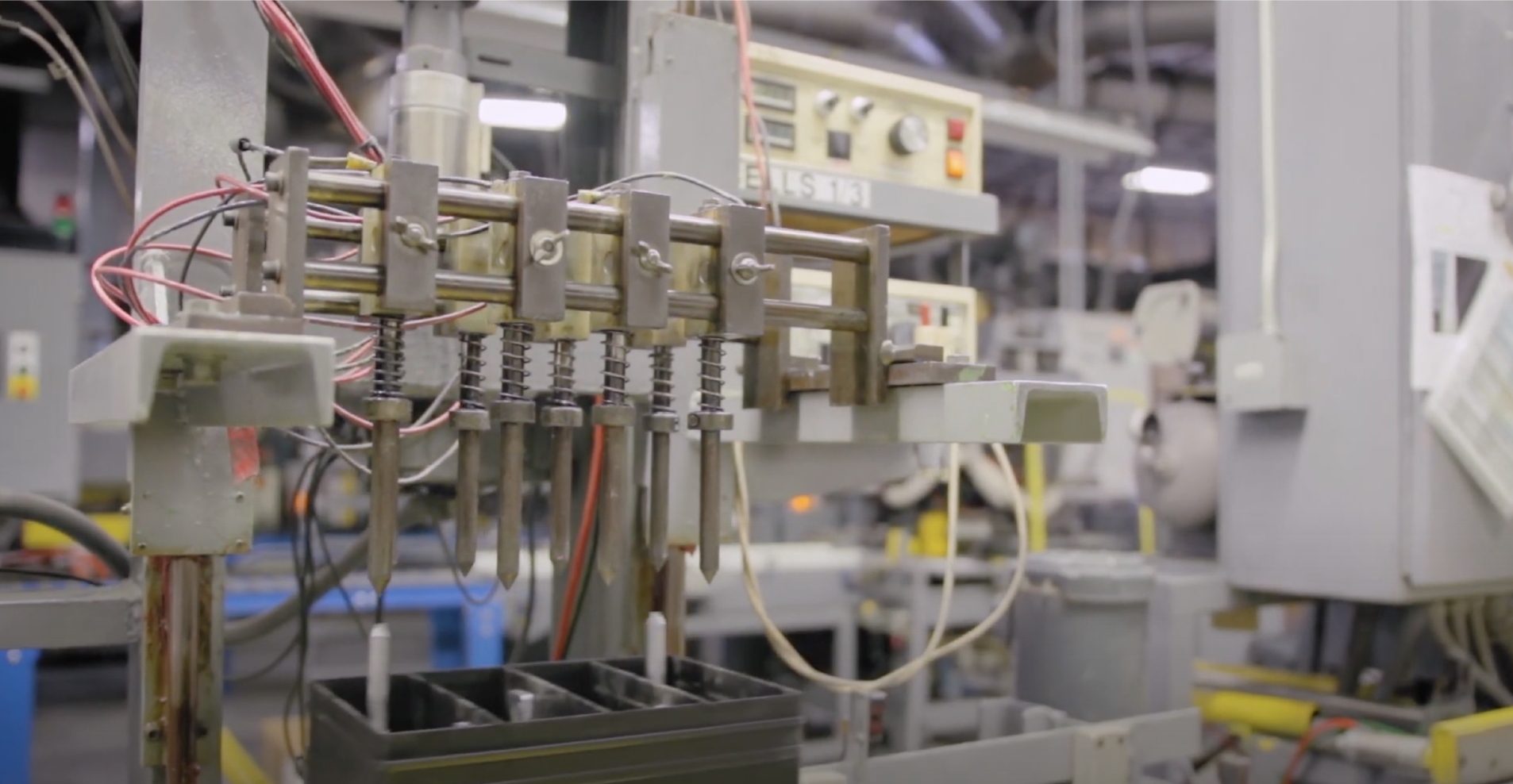

- Manufacturing Efficiency Over the last few years, Crown Battery commissioned a multi-million dollar capital investment in production automation, a 69,000-volt substation and industrial cell assembly. Additional investment is earmarked for greater advanced lead battery production and robotic assembly of industrial batteries.

- Sustainable Buying “Sustainability is a key buying requirement for us, and we aren’t alone,” said John Connell, vice president of SLI Products Group at Crown Battery. “More and more, our customers are asking, ‘Do you have a sustainability program in place?’ And companies have openly told us that they switched from prior suppliers to us because of our green manufacturing efforts.”

- Employee Safety Crown Battery is committed to extensive, career-long safety training for all employees. It has strict personal protective equipment and hygiene requirements for manufacturing employees, and it maintains two full-time, onsite registered nurses/wellness guides at its Freemont manufacturing plant.

Continuous Improvement: Looking Ahead to 2025

“We’re proud of our entire team for incorporating energy efficiency into their daily work,” says Hawk. “Their efforts make it possible for us to protect the local environment and bring good, safe jobs to Northwest Ohio and North America.”

Although Crown has already achieved an admirable record, Hawk is pushing the company to think “what’s next” and identified specific goals for 2025.

- Innovation Investment Crown will continue to collaborate with and co-fund joint R&D with the U.S. Department of Energy’s Argonne National Laboratory and other members of the Consortium for Battery Innovation to enhance the performance of lead batteries and the materials inside them.

- Manufacturing Investment Launch new efficiency programs and invest in even higher efficiency equipment to boost resource utilization and quality while reducing electrical use.

- Improve Recycling in LIMCs Extend support for programs to end informal battery recycling in low and middle income countries that lack proper safety standards by working with industry groups, NGOs and others.

- Strengthen Downstream Sourcing Encourage and incentivize raw material suppliers to use more renewable energy for production.

- Responsibly Sourcing Continue to reduce use of virgin-mined resources while building better/more batteries.

- Knowledge Transfer Enhance distributor technical training programs, including through Crown’s exclusive Commercial Service Center.

Giving Back: Well-Being of the World is the Heart of Crown Battery

For more than 20 years, Crown Battery has worked with the U.S. Export-Import (EXIM) Bank to expand to global markets. EXIM has helped Crown Battery to create jobs, expand production facilities, and give back even more to the Ohio community.

The company strives to be a societal force for good in the world, supporting important nonprofit organizations that solve problems like hunger, educational inequities and access to healthcare services. Some of its specific recipients include the Ronald McDonald House, community food banks across North America, Rotary International, and United Way.

Crown Battery has also established close relationships with regional government authorities and water and electricity suppliers to protect the environments where they operate.

The Power Behind the Performance: People

Crown Battery’s consistent efficiency and sustainability efforts have earned it numerous awards, including AEP Ohio’s Sustained Excellence Award (2020, 2015 and 2014), Continuous Energy Improvement Award (2016), and Energy Efficiency Champion Award (2013).

Hawk appreciates the acknowledgement, but he insists the company’s employees are the real winners.

“The power behind the performance, is our people,” Hawk said. “Without those folks we wouldn’t be the company we are today.”

Watch this video about employee investment the Crown way.

Thank you, Crown Battery, for letting us get to know you better!

Watch this space for other tour stops, as we travel the country sharing details about an industry that provides 60% of the world’s rechargeable energy storage and contributes billions of dollars to our domestic economy.Until then, read about Tour Stop #1 with Hammond Group, Inc.