We’re touring several U.S.-based battery manufacturing and recycling stars who help form the strong network of BCI member companies. They provide batteries and the services and supplies that are used to create those batteries. They also comprise the vast domestic infrastructure that ensures a reliable energy storage source exists to power the U.S. economy.

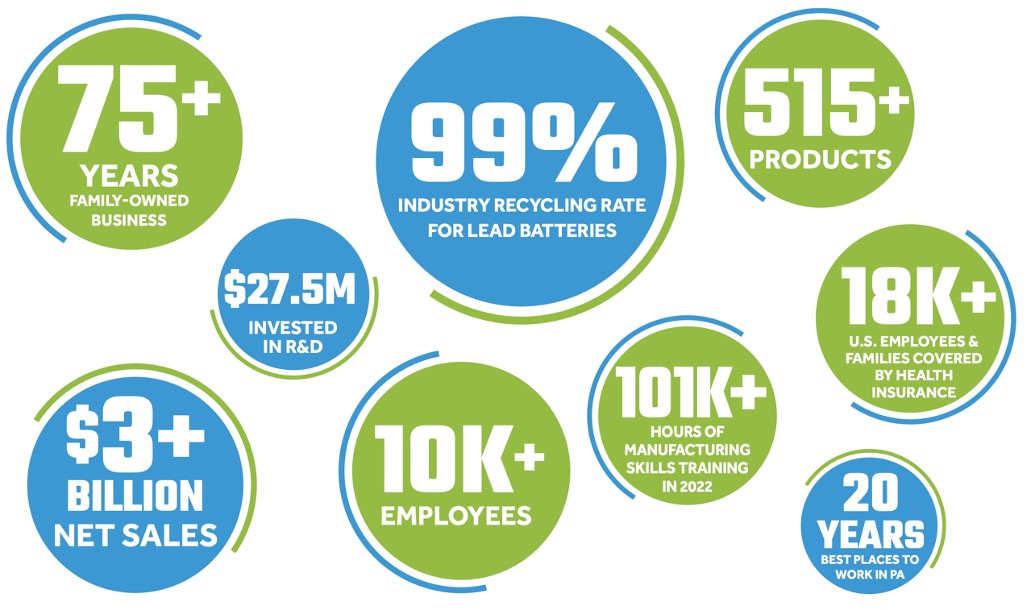

Pennsylvania-Based Company Exceeds $3 Billion in Sales, Employs Over 10,000

Though founded in a tiny town in Pennsylvania 77 years ago, modern-day East Penn Manufacturing is anything but small.

The privately held company had over $3 billion in sales for fiscal year 2022. And the resulting economic impact is striking: Over 10,000 jobs, $1 million annually in charitable giving, and operations that touch most states in the union, plus Canada.

Here’s a look at East Penn Manufacturing and its important role in the battery industry.

Geographic Footprint Reaches Far and Wide

East Penn operates the largest single-site, lead battery manufacturing facility in the world on 520 acres in Lyon Station, Pennsylvania, with additional world-class manufacturing, recycling and other supporting facilities. It has another lead battery manufacturing facility in Iowa, plus warehouses and distribution centers located in 35 states and Canada.

A Product Portfolio of Essential Applications

East Penn is doing critical work to help meet the growing demand for batteries. The company makes high-quality lead batteries and accessories, as well as other energy storage and system integration solutions. In the vehicle market alone, East Penn produces more than 515 battery types for cars, boats, motorcycles, forklifts and other vehicles, ranging in size from six pounds to over 50,000 pounds.

Consider these facts for the North American market:

- Transportation/SLI Batteries. East Penn is the second-largest provider.

- Motive Power Batteries. East Penn ranks second in manufacturing and sales.

- Reserve Power Batteries. East Penn ranks second in the valve-regulated lead battery market.

- Wire, Cable and Battery Accessories. East Penn is the largest provider of cable products.

A Global Employer Dedicated to Employee Development, Health and Safety

East Penn employees are located across the globe with a vast majority (7,800) working at the main Lyon Station campus, making East Penn the largest employer in Berks County, Pa.

A commitment to ongoing employee training and development is just one way the company empowers its workforce, according to East Penn Chairman Dan Breidegam.

“We power cars, trucks, boats, tractors and forklifts. We power hospitals, businesses, telecoms and military bases in emergencies. However, what we are most proud of is powering people, their careers, dreams and communities,” Breidegam said. That includes taking steps to drive employee engagement and retention, even though about 20% of the company’s workers have more than a decade of service.

In addition, East Penn is committed to providing a healthy and safe workplace for all employees. The global health and management system is the cornerstone of the safety culture. Each plant has a safety committee that meets once a month to assess risks and recommend facility and process improvements.

Innovation is in East Penn’s DNA

Despite the “East” in its name, innovation and progress are every direction you turn at East Penn.

“We always say that innovation is in [our] DNA,” said Norbert Maleschitz, East Penn Chief Technology Officer. “Innovation lets us turn big ideas into better products, solutions and operational practices that drive value, efficiency and sustainability.”

Here’s a sampling of East Penn’s major steps in continuous innovation:

- $27.5 million. The company’s annual R&D budget for 2022.

- The Breidegam Miksiewicz Innovation Center. The Lyon Station headquarters includes this 42,000-square-foot facility dedicated to R&D and continuous process and product improvement.

- Navitas Systems. In 2019, East Penn acquired this maker of lithium cells and energy storage products and systems for both commercial and U.S. Government/military customers.

- Greener Energy. East Penn has developed new innovations in clean energy storage, and its role in advanced lead-based technology supports all five powertrain iterations from start-stop micro hybrids to full EVs. The company also developed advanced battery solutions that support smart electrical grid technology and renewable energy generation.

- Public-Private Partnerships. Under an agreement with the U.S. Department of Energy’s (DOE) Argonne National Laboratory, East Penn and 14 other members of the Consortium for Battery Innovation, have joined battery-testing company Electric Applications to explore new ways to enhance the performance of lead and other materials in lead batteries.

“Sustainably is the only way … to grow”

For more than seven decades, East Penn has been developing recycling technology and raw material and energy conservation. Many of these investments have paved the way for advancements in sustainability and growth.

“East Penn’s growth has always gone hand in hand with our commitment to sustainability,” said East Penn CEO and President Chris Pruitt. “Sustainably is the only way we know how to grow.” To guide its sustainability efforts, East Penn has established an environmental management system at all of its manufacturing locations.

Other efforts include:

Recycling. Using a closed-loop approach to environmental sustainability and protection: East Penn’s recycling facility processes approximately 30,000 batteries per day, efficiently recycling and reusing all three major components of a lead battery. With its 98% recycled material, the company’s full line of transportation batteries has the highest UL Recycled Content Validation for batteries in the world.

Emissions. Employing the most advanced control technology available to reduce lead emissions into the air, wastewater and stormwater: East Penn began deployment of High-Efficiency Particulate Air (HEPA) filters in its facilities over a quarter century ago.

Water stewardship. At Lyon Station, using ultramodern wastewater distillation and a treatment plant: In 2022, East Penn reused a total of 44 million gallons of wastewater.

Energy conservation and renewable technologies. Participating in the U.S. DOE’s Better Plants program: East Penn has committed to a 20% reduction in energy use per unit of production by 2028 against a 2018 baseline. East Penn is also on track to use 5% solar powered energy at its main campus annually.

A History of Serving the Community

Each year, East Penn donates more than $1 million to charitable organizations. The company is among the top 10 supporters of United Way in Berks County. In fact, in 2022, corporate and employee contributions to United Way totaled $778,353, which went to support 80 programs.

Beyond the corporate program, thousands of co-workers offer their time, talents and financial resources annually to support organizations and causes that build a stronger community. That includes food pantry donations and an annual holiday toy drive.

Thank you, East Penn Manufacturing, for letting us get to know you better!

Watch this space for other tour stops, as we travel the country sharing details about an industry that provides nearly 45% of the world’s rechargeable energy storage and contributes billions of dollars to our domestic economy. Until then, read about Tour Stop #1 with Hammond Group, Inc., Stop #2 with Crown Battery and Stop #3 with Gopher Resource.