We’re touring several U.S.-based battery manufacturing and recycling stars who help form the strong network of BCI member companies. They provide batteries and the services and supplies that are used to create those batteries. They also comprise the vast domestic infrastructure that ensures a reliable energy storage source exists to power the U.S. economy.

Headquartered in Alpharetta, Ga., Stryten Energy is a leading U.S.-based manufacturer with more than 14 gigawatt-hours of energy storage production capacity annually. Stryten provides advanced lead, lithium and vanadium battery solutions, intelligent chargers and energy performance management software. Founded on 130 years of battery expertise, Stryten Energy employs more than 2,500 people across 10 U.S. manufacturing plants and four R&D centers.

The Strength of Stryten Energy

Stryten Energy is not betting on any one battery solution. Instead, the company believes the future will involve a variety of technologies. Stryten offers a complete offering of advanced lead, lithium and vanadium batteries, allowing customers to select the right chemistry or combination of chemistries to design a solution that best fits their energy needs.

Stryten’s premium solutions for industry-specific applications are delivered through five focused divisions:

- Essential Power solutions deliver reliable energy to critical systems in need of clean and dependable power supply.

- Motive Power provides the energy storage and charging solutions needed for industrial operations.

- Transportation power solutions range from conventional flooded batteries to advanced technologies, including Enhanced Flooded Batteries (EFB) and Lithium-Ion batteries.

- Military and Government provides reliable and powerful batteries for combat vehicles, submarines, military communication systems and more.

- Energy Components uses a proven plastic injection molding methodology to produce critical automotive, motive and essential power battery components.

Solving Energy Storage Challenges

Stryten Energy is at the forefront of advancing domestic energy storage in the U.S. through its battery manufacturing expertise across a wide range of projects.

In August 2023, Stryten Energy installed a VRFB system with Snapping Shoals EMC, an electric cooperative in the Atlanta metro area. The system was specifically designed and sized to conduct long-duration testing that is six hours or more. This project is the first VRFB energy storage system manufactured and installed in Georgia.

“This demonstration project is an important step to proving the capabilities of VRFB technology in utility use cases such as energy cost control, peak shaving and avoiding curtailment. Our partnership with Snapping Shoals provides the ideal platform to test the VRFB system and show the potential impact of Georgia companies working together to bring clean energy to the state,” said Mike Judd, CEO and President of Stryten Energy.

A lead battery energy storage system (BESS) is installed at VICARS Community Center, connecting the BESS to a new microgrid, solar array and the legacy power grid. This resiliency hub will provide the community access to reliable power for their essential devices, continue to receive information as emergency situations develop, store medications sensitive to temperature, and safely gather in the aftermath of an emergency or severe weather event. The project went live in July 2024.

Atlanta Mayor Andre Dickens, Representative Nikema Williams and EPA Administrator Michael Regan joined Pastor Kevin Early for the ribbon-cutting at Vicars Community Center.

Stryten Energy has received a contract award from the Defense Innovation Unit’s (DIU) FAStBat project to develop and evaluate a prototype 6T lithium-ion battery and potentially extend the technology to other cross-service platforms. The FAStBat program seeks to support the domestic growth of manufacturing capacity to underpin the United States defense industrial base.

Stryten is investing in domestic lithium battery assembly to support its next-generation lithium battery production for military, essential power and industrial applications. Stryten plans to source 100% domestically made lithium cells as the U.S. lithium battery supply chain and manufacturing capabilities mature. Production will launch in early 2025 and will initially support Stryten’s military and industrial customers.

Stryten has also been awarded Phase One MAKE IT Prize funding to build a domestic vanadium electrolyte manufacturing plant to support long-duration energy storage. The Securing America’s Vanadium Electrolyte Supply (SAVES) project will deploy Stryten’s proprietary reactor design to provide domestically produced, low-cost electrolyte.

Pictured Left to Right: Mike Judd, Chief Executive Officer and President, and Petar Oklobdzija, Executive Vice President and Chief Financial Officer

Stryten Energy recently announced a partnership with Dragonfly Energy to distribute a mix of existing Battle Born Batteries brand of lithium-ion batteries for automotive aftermarket applications and jointly develop new battery models specifically tailored to Stryten’s target markets.

“The addition of Dragonfly Energy’s Battle Born Batteries into our transportation product portfolio provides our customers access to a well-known brand of quality lithium batteries. With this partnership, Stryten now has a complete lithium battery portfolio to meet our customer needs across multiple industries,” said Mike Judd, CEO and President of Stryten Energy. “Dragonfly Energy’s mission to produce American-made lithium batteries complements Stryten’s vision to provide our customers access to a domestic supply chain and circular economy for lithium batteries.”

Stryten Energy commemorated the opening of its expanded, state-of-the-art battery testing laboratory in August 2024. The lab will support Stryten Energy’s engineering, research and development, and quality assurance departments, as well as manufacturing facilities, in new product development, technology evaluations, warranty investigations and root cause analysis.

A proclamation from Lieutenant Governor Burt Jones in recognition of the celebration stated, “Stryten Energy forging a brighter future for economic development in Georgia and fulfilling a shared commitment to innovation and growth, harnessing collective talents for the prosperity of the state of Georgia.”

Pictured left to right: Roger Miksad, President & Executive Director of BCI; Tim Vargo, Chairman of the Board, Stryten Energy; Mike Judd, CEO & President, Stryten Energy; Nathan Barker, Legislative Director to U.S. Representative Rich McCormick (GA-06); Ronnie Joyner, Senior Manager, Laboratory, Stryten Energy.

Elevating the Message About Sustainability

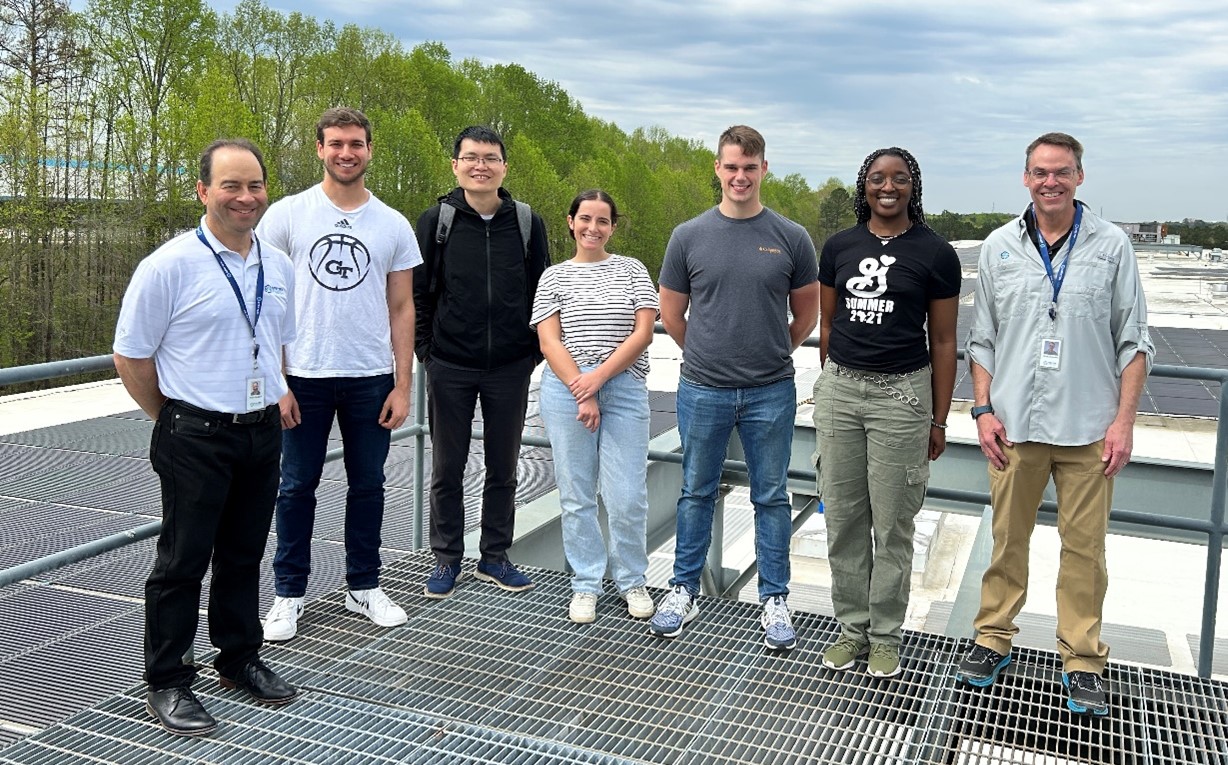

Brian Berland, Senior Director of VRFB Products (far left) and Scott Childers, Vice President of Essential Power (far right) gave a tour of the Stryten HQ microgrid to students from the Georgia Institute of Technology.

The circular economy of the U.S. lead battery industry is a model for other industries working towards the sustainability of their manufacturing, distribution and recycling processes. At Stryten Energy, each lead battery produced in its U.S. manufacturing plants is made with 90 percent recycled material. And for every battery produced, Stryten recycles the equivalent of that battery through its North American-based recycling partners.

Stryten Energy’s corporate headquarters is equipped with a fully functional microgrid. The original system was designed in 2008-2009 to support the 24×7 operations of the data center that previously occupied this space.

Stryten will replace the old array with a new system. In addition to the current UPS battery, the company will be adding a lead BESS. This BESS will be used for peak shaving during high demand use period and will level total power consumption from the grid each day. Stryten will have complete access to control the system for any future research and development needs and will be an onsite testbed for energy storage technologies.

Bringing Endless Energy to Our Communities

At Stryten Energy, we are committed – to each other, our customers and our communities. Our employees donate to toy and food drives, volunteer for Adopt-a-Highway events, organize e-waste recycling events, sponsor country fairs and provide festival shuttle rides. Our plants provide tours for high school and college students, as well as state and federal policymakers, to help them learn about the battery manufacturing industry.

U.S. Senator Joni Ernst (R-IA) visited the Manchester battery manufacturing plant and participated in a Q&A session with employees.

Food drive donation at the Stryten Energy office in Ottawa, Canada.

Middle school students learned about manufacturing careers at Stryten Energy’s Lampeter plant.

Sock drive donation for the homeless at the Stryten Energy facility in Kansas City, MO.

Stryten Energy employees have also founded their own charitable organizations to serve their communities.

Michael Bergen, Maintenance Team in Kansas City, KS, established Hands to Heart, a not-for-profit and volunteer organization that delivers toys to low-income families throughout Kansas, Missouri, Nebraska and South Dakota. In the first year, he served about 50 kids. Now, 29 years later, his organization is delivering toys to more than 11,000 kids in need during the holiday season.

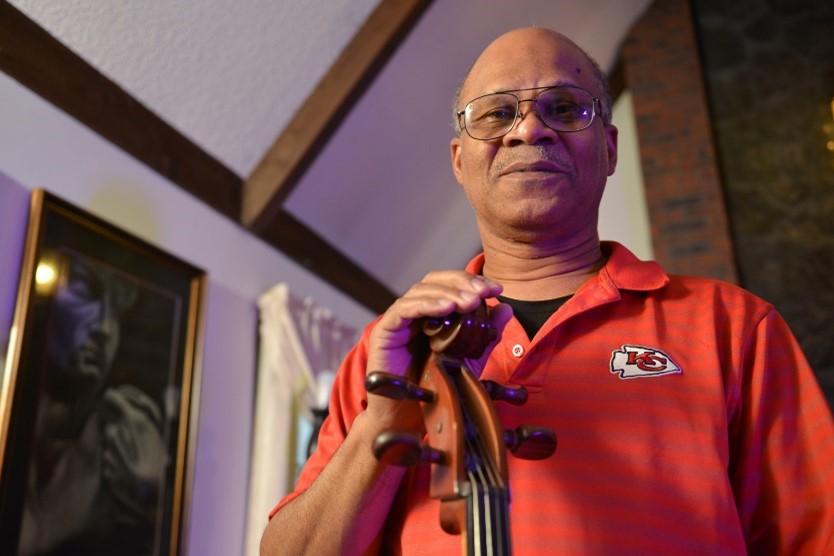

Darryl Chamberlain, Stryten Technical Writer, in Kansas City, MO, founded the A-Flat Youth Orchestra and the A-Flat Music Studio Inc. were founded by Darryl to help fill the gap from the lack of school-sponsored music programs. The A-Flat Music Studio provides instrumental music instruction for students in Kansas City for a very affordable cost and is the developing agency for the A-Flat Youth Orchestra. Darryl estimates that he has served about 400 students since the Music Studio opened its doors in 2005.

Stryten Energy is also a proud sponsor of Rivers of Recovery, an innovative, national nonprofit that uses outdoor-based activities to effectively treat symptoms of post-traumatic stress, depression, and anxiety in combat veterans and active-duty military. The organization has achieved national media attention for its unique programs and results-driven treatments, which combine fly fishing and other outdoor activities with a scientifically designed curriculum of therapeutic techniques. As a part of the sponsorship, veteran employees from Stryten Energy will have the opportunity to participate in several fly-fishing trips alongside Rivers of Recovery guides.

Pictured Left to Right: Levi Crawford, Marketing Director, Rivers of Recover; Amy Simon, Executive Director, Rivers of Recovery; Rodger Meyer, Executive Vice President of Operations, Stryten Energy; Petar Oklobdzija, Executive Vice President and Chief Financial Officer, Stryten Energy

“We chose Rivers of Recovery to support because we can make a bigger impact and because we have direct access,” said Mike Judd, President and CEO of Stryten Energy. “We see people’s faces who participate in the programs. This organization is directly impactful to folks on the ground who have been in combat, and we see the results.”

Thank you, Stryten Energy, for letting us get to know you better!

Watch this space for other tour stops, as we travel the country sharing details about an industry that provides nearly 45% of the world’s rechargeable energy storage and contributes billions of dollars to our domestic economy. Until then, read about Tour Stop #1 with Hammond Group, Inc., Stop #2 with Crown Battery, Stop #3 with Gopher Resource, Stop #4 East Penn Manufacturing, Stop #5 ENTEK International, and #6 EnerSys.