Turn a key or push a button and an engine starts. Dial a number and your call is connected. Order online and groceries are delivered to your door. We owe many conveniences of modern life, including critical services during the pandemic, to batteries.

That’s why we celebrate National Battery Day annually on February 18. It’s the birthday of Alessandro Volta, an Italian physicist, chemist and pioneer of electricity who is credited as the inventor of the electric battery.

But this year, the day is especially poignant. Lead batteries have been essential to surviving COVID-19. And, they’ll play a critical role in our country’s economic recovery.

Lead Batteries Help Us Persevere Through the Pandemic

It’s been almost a year since the virus triggered lockdowns. But when schools, restaurants and businesses closed their doors, our facilities remained open and our essential employees stayed on the job so others could work and learn remotely.

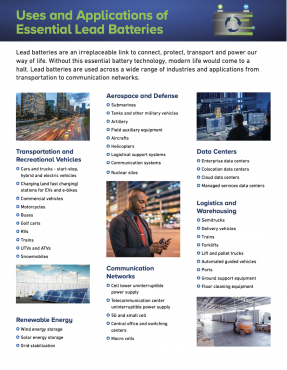

Lead batteries’ dominant role within essential services has demonstrated how critical batteries were to the first wave of the pandemic response – and beyond. Here are some examples.

- First Responders. Lead batteries ensure emergency vehicles for first responders start every time.

- Backup Power. Lead batteries provide the backup power to keep hospitals operating during power outages, instantaneously bridging the minutes until a generator kicks in. Fact: Lead batteries serve 92% of the demand for uninterruptible power supply to prevent blackouts from becoming life-threatening emergencies.

- Online Shopping Logistics. Without question, online shopping has skyrocketed. Warehouse and logistic services have become our automated personal shoppers, moving millions of packages and pallets of goods daily. Lead batteries provide 90% of the motive power demand in applications such as forklift trucks. The batteries also power the semis, vans and sedans, which crisscross the nation delivering goods to our doorsteps.

- Connectivity. The ability to work and learn remotely has been enabled by a complex communications grid of data centers, 5G, and a telecommunications system which relies on lead batteries, the dominant technology in this space for backup power.

Lead Batteries and Vaccine Distribution: Delivering Hope

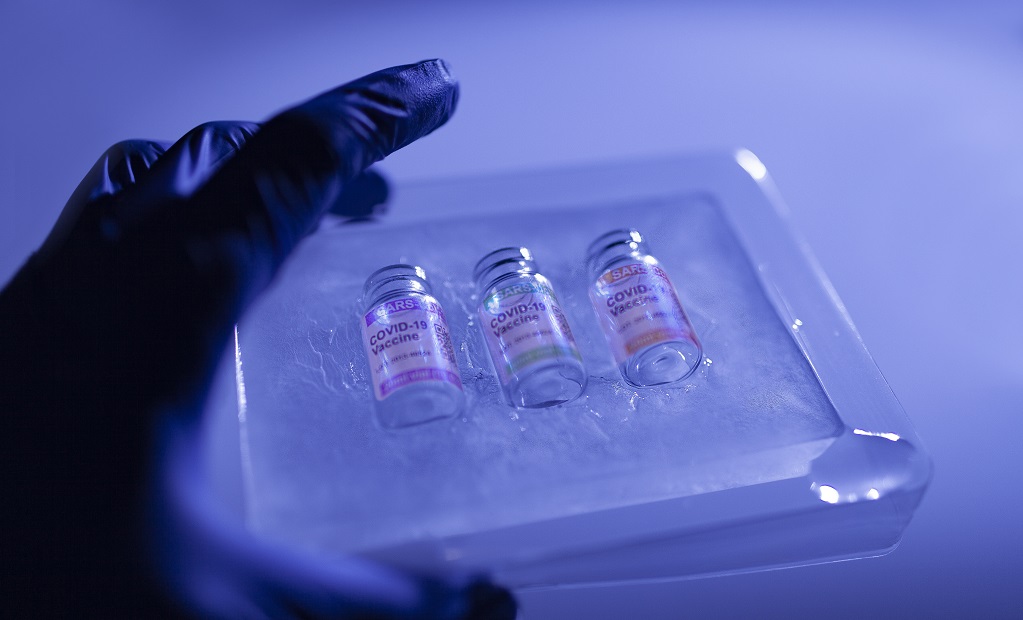

The pandemic has moved into a second phase, with the approval of two vaccines in the U.S. As pharma companies begin shipping millions of vials of vaccines, lead batteries are involved in all points of the manufacturing, distribution and delivery process.

The first-approved vaccines require refrigeration at sub-zero temperatures to maintain effectiveness. Refrigerated trucks rely on lead batteries to keep the cold storage systems running to protect their precious cargo. Thermo King, an expert in pharmaceutical transport and storage solutions, estimates that without correct shipping, 25% of vaccines would reach their destination in a degraded state.

After arriving at their destination and before administration, lead battery-powered backup systems keep vaccines stored at the required temperature, should there be a power failure.

Leads Batteries Key to “Build Back Better”

A third phase of the pandemic is moving forward into economy recovery. Lead batteries will play a significant role in strengthening our infrastructure, including national security, transportation, communications and climate mitigation efforts.

There is strong market demand for lead batteries, with an expected 6% CAGR through 2030. Plus, a robust domestic and circular manufacturing and distribution network, and a skilled workforce, position lead batteries for their important role in providing jobs and infrastructure to get back on track.

Providing More Green Jobs

A greener economy is in our future, starting now. Lead batteries, with their closed-loop, domestic, ready-to scale infrastructure, are ready.

In the U.S., 99% of all used lead batteries are recycled, and 80% of a new lead battery is typically comprised of recycled material. In fact, all three major components of a battery (lead, electrolyte and plastic) are 100% recyclable. This creates thousands of green jobs within the lead battery recycling sector.

Lead batteries are also essential to climate change mitigation:

- Renewable Energy. Demand for renewable energy is expected to double by 2050. Lead batteries provide the energy storage needed to bank excess solar and wind power, ensuring a steady supply of electricity when the sun isn’t shining or the wind isn’t blowing. This load leveling will become increasingly important.

- Greenhouse Gas Reduction. Start-stop technology in vehicles, enabled by lead batteries, removes 4.5 million tons of greenhouse gas emissions in the U.S. each year.

Essential to National Security, Communications, Transportation

The industry’s domestic, scalable infrastructure ensures batteries are available for critical uses. More than 90% of the demand for lead batteries in the U.S. is met by North American lead battery manufacturers. Manufacturing lead batteries with U.S. materials, means:

- Supply Chain Resilience. The supply chain doesn’t experience the same foreign-trade disruptions as other business sectors.

- Data Security. The nation’s $1 trillion communications infrastructure runs on lead batteries. This supports our national security through ensuring data centers, telecom and the military have a reliable source of power.

- Logistics. Our transportation system relies on lead batteries to move people and materials via rail, air, ship and highways. Warehouse operations, which have become increasingly important, rely on electric forklifts to keep logistics of goods and services on track, and 90% of that market demand is met with lead batteries.

Committed to Global Leadership

These achievements are the result of the industry’s commitment to meeting changing market needs by investing in research and development. In 2019, the industry invested $105 million in research. Fifteen lead battery companies are currently engaged in a partnership with the Department of Energy’s Argonne National Laboratory to improve battery performance. And, as an active participant in the DOE Energy Storage Grand Challenge, we support the U.S. goal to be the global leader in battery technologies and clean energy.

President Joe Biden has recently said that global leadership in battery technology is “up for grabs.” On this National Battery Day, the lead battery industry reiterates its commitment to answer the challenge for U.S. leadership.