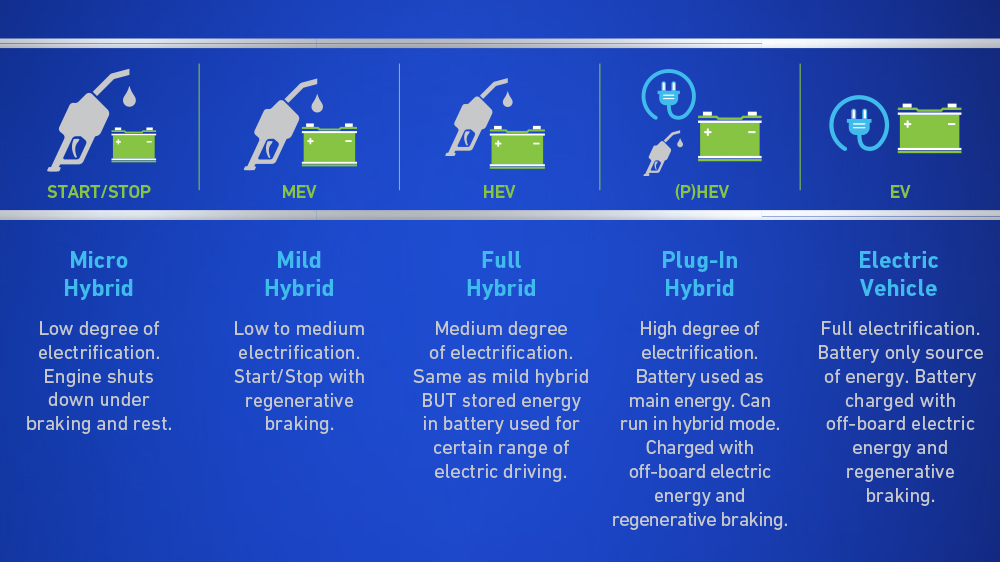

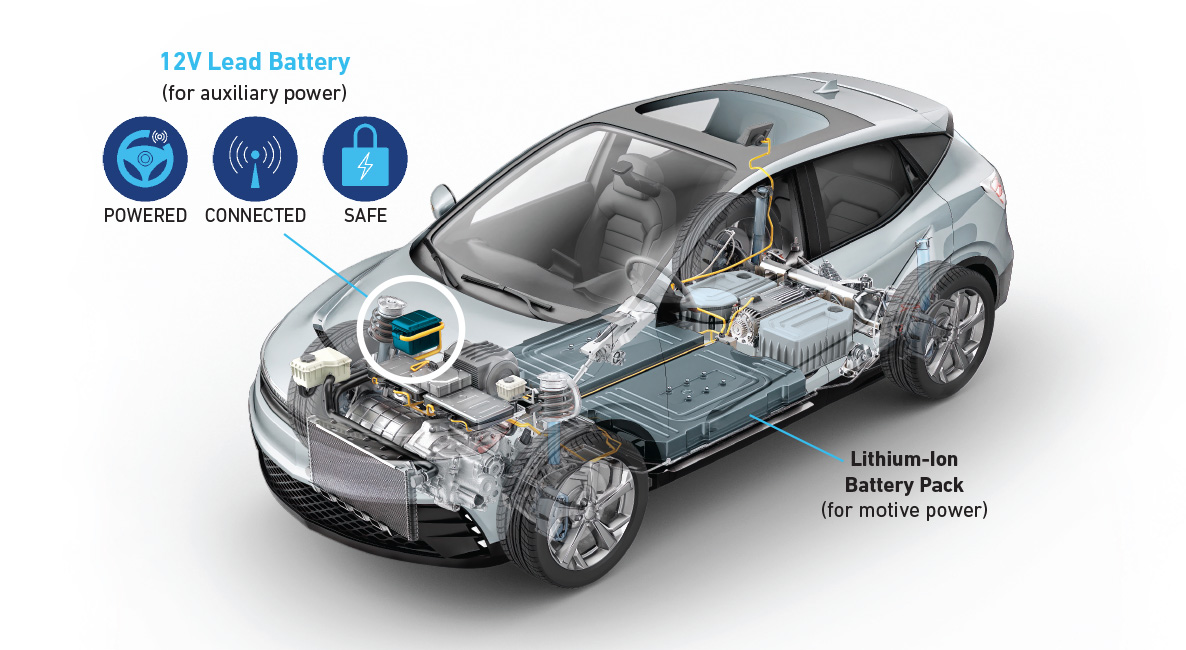

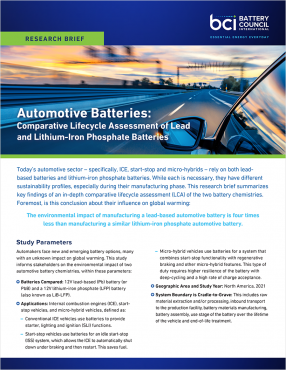

Batteries are at the heart of the automotive industry, powering everything from internal combustion engine (ICE) vehicles to electric vehicles (EVs) and charging stations. These energy storage solutions ensure reliable performance, efficiency, and safety, driving the future of transportation.

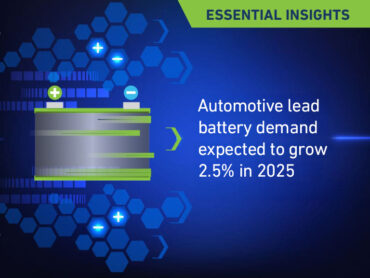

Lead batteries maintain growth trajectory in North...

A new report highlights the enduring role of advanced lead batteries in the evolving U.S. vehicle marketplace, and forecasts modest but...

Article

September 22, 2025