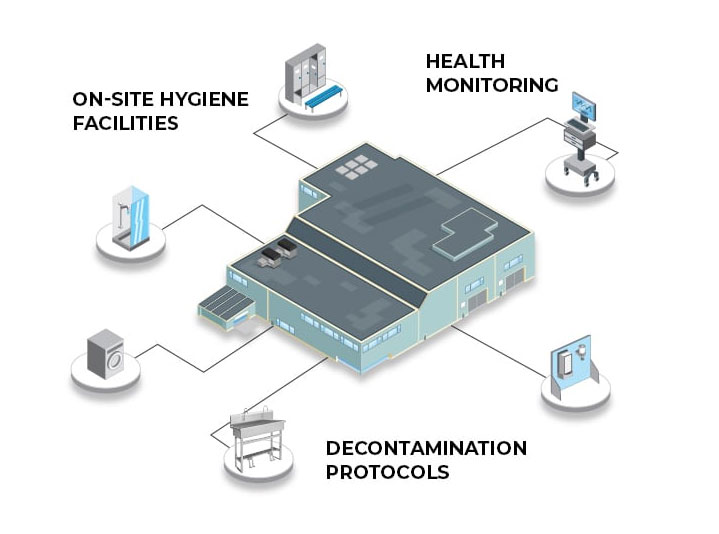

Employee health and safety is a core priority for North American lead battery recyclers. BCI members uphold rigorous safety and environmental standards to protect workers, communities, and the environment while supporting a sustainable battery supply chain.

Employee Safety

Lead battery manufacturers and recyclers strive to exceed OSHA standards and are continually advancing to protect employees, the community...