Battery Council International President Roger Miksad makes the case for why lead batteries must receive equitable funding for R&D, in a recent article published by Innovation News Network (INN). INN is a go-to source for the latest news dedicated to research, emerging science, policy and innovation topics across the globe. This article is reprinted from INN online and The Innovation Platform Issue 16 with permission, copyright 2023. Note: Because INN is published in the U.K., some words may use the British spelling.

As the news focus remains on lithium batteries, Roger Miksad, President of Battery Council International, explains why the role of lead batteries in the industry must not be forgotten.

As President Biden and Congressional leaders negotiate economic packages to boost American competitiveness by boosting our energy storage leadership, the nation’s leaders must ensure they support the incumbent, but often overlooked, domestic battery manufacturing sectors such as lead batteries.

A century of commitment: Educating and empowering for the future

Battery Council International is the leading North American industry association for battery manufacturers and recyclers. We are committed to promoting policies recognising the importance of sustainably manufactured batteries to our economy, energy security, and the environment.

As the association reaches its 100-year milestone next year, we are reinvesting in our mission to educate the public and policymakers on the essential role that batteries play in powering our daily lives, and the strength of America’s long-standing battery manufacturers.

Lead batteries: An established sustainable solution

While lithium-ion batteries have captured recent headlines, the industry’s most-proven technology, the workhorse lead battery, continues to power the vast majority (99.7%) of the nearly 300 million vehicles of all types operating on the road today. In the US, they also form the backbone of the critical backup power that keeps critical infrastructure like data centres, hospitals, and telecom networks online 24/7.

Lead-based batteries may have existed for over 100 years, but the modern lead battery is not your grandfather’s car battery. Today’s next-generation batteries and ongoing discoveries hold the promise to unlock groundbreaking advances in battery performance while building on a proven and reliable foundation. With focused research and development (R&D), lead batteries could become even more powerful, efficient, and sustainable.

But federal funding has lagged; today, most U.S. Department of Energy (DOE) battery funding is focused on lithium-ion chemistries. While important to the overall mix of battery chemistries, this creates an R&D imbalance and misses the opportunities to maximise lead battery capabilities for transportation and energy storage applications.

A secure domestic supply chain already exists

Lead batteries are uniquely poised to leverage a fully established and secure domestic industrial base to serve new national priorities such as energy storage for renewables and grid resilience.

Lead batteries also avoid the material sourcing conflicts that plague batteries depending on rare-earth minerals. The full lifecyle of lead batteries occurs within America, from manufacturing to recycling and then manufacturing new batteries from those recycled elements.

According to Battery Council International statistics, the lead battery industry supplies over 90% of US forklift and industrial motive power batteries.

Further, over 99% of end-of-life lead batteries in the US are recycled, with recovered materials directly returning to new batteries, making them a sustainable storage solution. This high recycling rate also provides manufacturing stability, as domestically recycled lead is used to produce new batteries and reduce the impact of mining.

Versatility of lead batteries

Lead batteries form the backbone of large-format and low-voltage battery storage across all applications – automotive, forklifts, data centres, and home energy storage. The domestic lead battery industry has pioneered innovations for decades, leading to repeated increases in power, energy, and lifespan.

Innovations like absorbed glass mat (AGM) and enhanced flooded batteries have maintained lead batteries as the dominant automotive battery for internal combustion support by providing stronger starts and increased regenerative braking capabilities.

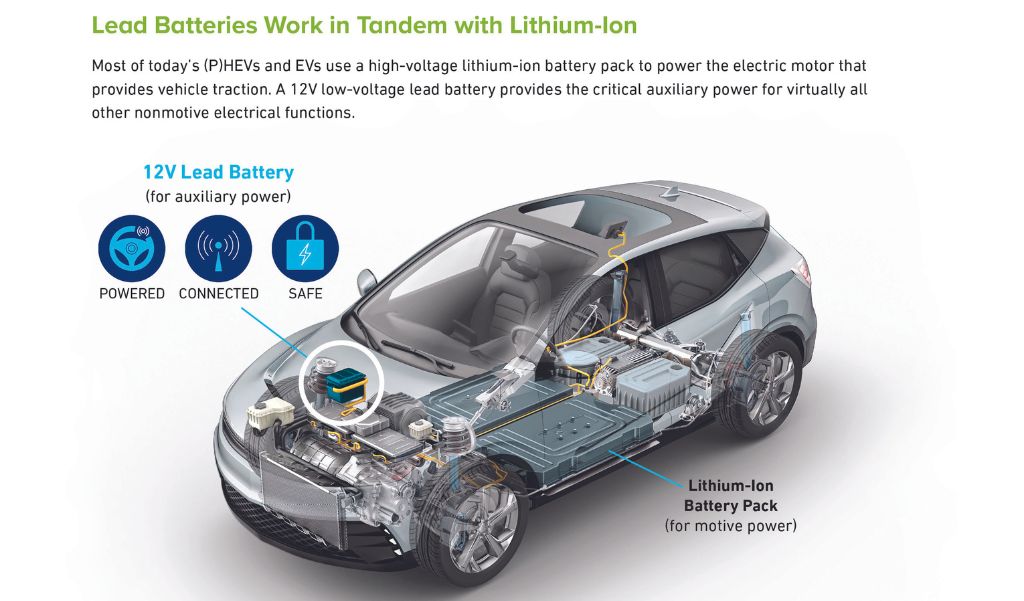

Lead batteries are also the dominant choice for low-voltage and emergency system support systems for electric vehicles due to their proven reliability, durability, and low cost.

The US Energy Information Administration states that the transportation sector accounted for over 25% of US greenhouse gas emissions in 2021. With sustained support, advanced lead batteries can play an even greater role in reducing transportation emissions through improved fuel efficiency and increased adoption of hybrid and electric vehicles. For example, start-stop vehicles enabled by lead batteries reduce greenhouse gas emissions by nearly ten million tons annually in the US.

Next-generation lead battery chemistries and configurations on the drawing board, such as bi-polar lead batteries, show continued promise. With deeper national investment in research funding, lead batteries could provide even greater performance at lower costs than some lithium-ion applications.

With the right investments, lead batteries will be a significant part of our nation’s energy storage backbone while complementing growth in lithium-ion batteries. According to the DOE’s Energy Storage Grand Challenge roadmap (ESGC), lead batteries are well-positioned to meet short duration storage needs by 2030 across transportation, defence, and the electric grid.

More recently, the DOE’s ESGC Technology Strategy Assessments found that lead-based technologies can achieve the DOE’s cost goals for long-duration energy storage at a lower R&D cost than any other technology.

Similarly, flow batteries utilising low-cost and abundant materials stand poised to deliver large-scale storage in a robust and highly scalable way. Flow batteries offer scaling capacity by simply increasing the volume of electrolyte storage rather than deploying additional batteries.

Federal funding must prioritise American energy independence through battery innovation

US battery manufacturers have a plan to enhance domestic production and innovation. But current federal funding is improperly tilted in favour of a handful of technologies, has failed to support the existing US industry, and does not reflect the nation’s existing and future reliance on lead batteries across every sector.

Equitable R&D investment can help the US to solidify its global leadership in lead battery manufacturing and recycling. The lead battery industry directly employs more than 121,000 Americans across the country. Increased support for lead battery R&D will lead to good-paying domestic jobs that produce and recycle batteries as part of the electrification transition.

Federal funding that equitably balances support across all viable battery technologies, including lead, flow, lithium-ion, and other technologies, will maximise return on investment for taxpayers. With sustained R&D support, the innovative American lead battery industry can continue powering today’s and tomorrow’s vehicles and expand into new markets and applications. But their full potential remains locked without commensurate federal funding.

Budget negotiators and agency administrators alike should avoid picking winners and losers. A balanced ‘all of the above’ strategy will enhance energy storage across automotive, utility and defence sectors. Renewed investment in lead battery R&D will deliver value for American workers, businesses, consumers, and our environment. With emerging chemistries, recycling innovations and advanced manufacturing processes, the future for lead batteries made in America looks brighter than ever.

Congress must also pass the USA Batteries Act (HR 1594) to remove taxes on key domestic battery manufacturing raw materials. These taxes penalise domestic battery manufacturers by putting them at a competitive disadvantage to their foreign counterparts. These taxes also reduce the ability of manufacturers to invest in the R&D needed to remain globally competitive.

The future will build on domestic battery industries

The demand for energy storage will continue growing exponentially in the coming decades. To achieve energy independence, we will need batteries of all types: Lead, lithium, flow, and chemistries yet to be discovered. But the viability of the nation’s energy storage strategy rests on the shoulders of the reliable batteries already powering America’s vehicles and grid each day.

We must begin with the solid foundation we already have in place – the innovative companies and workers driving American lead-battery manufacturing and recycling forward each day. With the right investments in R&D, their best days lie ahead.

Congress must support the equitable, balanced funding needed to maximise our investments in proven domestic battery industries. By doing so, we can secure American energy independence, create good jobs, and build a sustainable future powered by the full range of incredible homegrown innovations.

Please note, this article also appeared in the sixteenth edition of The Innovation Platform, page 118-121.