BCI Celebrates Battery Industry’s Commitment To Meet the Needs of the Next Century

Batteries may be small in size, but their impact is mighty. They are a cornerstone of the modern U.S. economy, powering cars and trucks, heavy duty farming and mining equipment, warehouse forklifts, telecom and data center backups, and smart-grid energy storage solutions.

Battery Council International (BCI) is proud to mark Manufacturing Day 2024 by highlighting the critical role of battery manufacturers and their suppliers. For over 100 years, BCI has represented battery manufacturers, suppliers and recyclers. Today, BCI and its 160+ members are supporting U.S. economic growth through secure domestic supply chains and resilient battery manufacturing that can meet the nation’s future energy needs.

“Stakes are higher than ever”

Roger Miksad, BCI’s president and executive director, says the stakes are higher than they’ve ever been for the battery industry.

“Batteries are a critical component across a host of essential applications, from electric vehicles and transportation, to telecommunications, alternative power and agriculture,” Miksad explained. “But there are challenges, too, like an aging energy grid and supply chain uncertainty.”

He is confident battery manufacturers are up to those challenges.

“BCI and its members are leveraging constant growth and innovation to confidently meet the needs of the next century.” Below are notable highlights of the U.S. battery manufacturing industry.

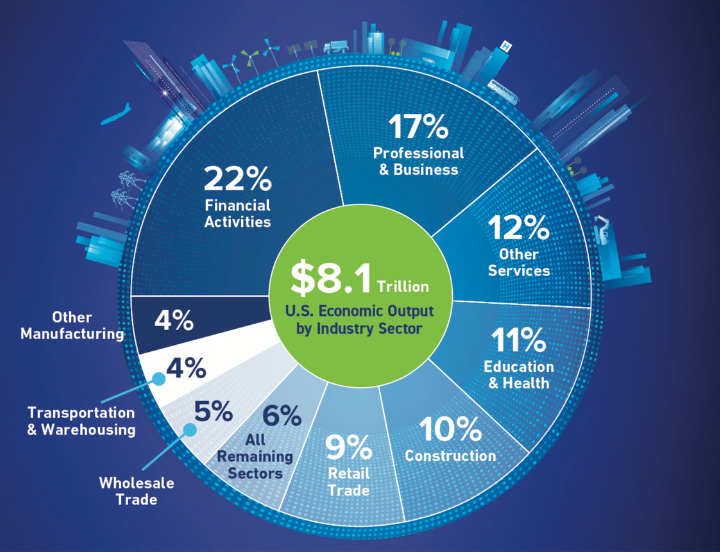

Economic Impact of Battery Industry

According to a 2024 report, the U.S. battery industry has a massive economic impact of $8.1 trillion, including 48 million U.S. jobs that are related to, or reliant on, the battery industry.

U.S. lead battery manufacturers as a group directly contribute roughly $3 billion in tax revenue annually, and these battery manufacturers and related suppliers provide more than 121,000 U.S. jobs.

Wages are 36% higher for recycling and mining workers in the industry and 25% higher for battery manufacturing workers. Across all lead battery job roles, the average salary is more than $81,000.

Domestic Infrastructure Protects Supply Chains

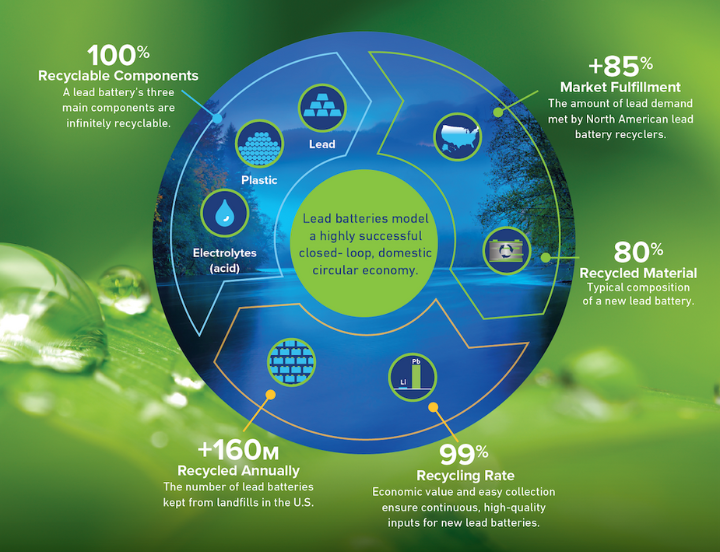

The lead battery industry’s vast North American infrastructure and proven circular model are ensuring the industry can help meet the demand for critical and clean energy storage. In fact, the industry’s established circular infrastructure is a model for other battery chemistries – and industries – in how to responsibly source, use, reuse and manage materials.

Furthermore, this proven manufacturing model is helping to inoculate the industry to supply chain disruption from trade policies and trade interruptions. Some industry facts about U.S. lead batteries:

- They boast a 99% recycling rate, making lead batteries a model of resiliency and reliability.

- A new lead battery is typically comprised of 80% recycled material.

- The lead in lead batteries is infinitely recyclable.

Innovating for Future Needs

In 2024, the Department of Energy (DOE) awarded $5 million to BCI to form an industry consortium focused on long-duration energy storage research in collaboration with three national labs.

Beyond its lead and lithium workstreams, BCI also operates a Flow Battery Industry Group dedicated to this uniquely scalable technology. This industry group was separately awarded a DOE grant in 2024 to continue its research into next-generation battery manufacturing.

Unmatched Safety and Sustainability

For nearly 30 years, BCI has worked cooperatively with the Occupational Safety and Health Administration (OSHA) on voluntary safety programs, worker training and rulemakings. In fact, BCI’s members enforce stricter blood lead levels for workers than required by OSHA.

North America’s battery recycling network safely collects more than 8 billion pounds of spent lead batteries annually, making lead batteries the most recycled product for more than 30 years. BCI is working closely with private and public stakeholders to build on this success and apply lessons to other chemistries, including lithium-ion batteries.