In an era where sustainable practices are no longer optional but essential, the battery industry continues to raise the bar for recycling excellence. As America celebrates America Recycles Day on November 15, 2024, the lead battery industry stands out as a blueprint for achieving a circular economy.

Breaking records in the recycling revolution

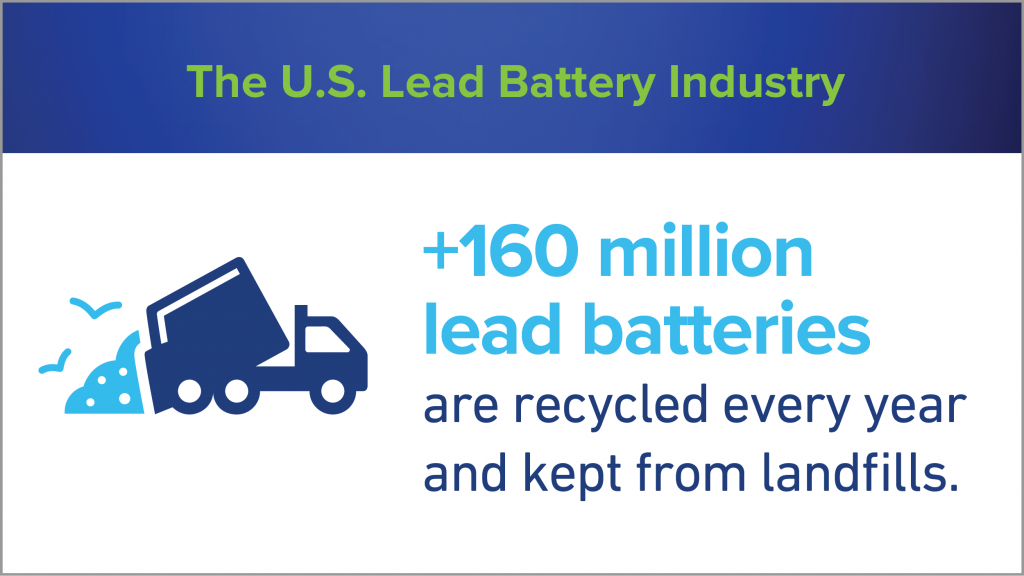

While many industries strive to improve their recycling rates, lead batteries have maintained their position as America’s most recycled consumer product with an unprecedented 99% recycling rate. This achievement isn’t just about numbers – it represents a sophisticated ecosystem that keeps more than 160 million lead batteries from entering landfills each year, demonstrating what’s possible when an industry commits to environmental stewardship.

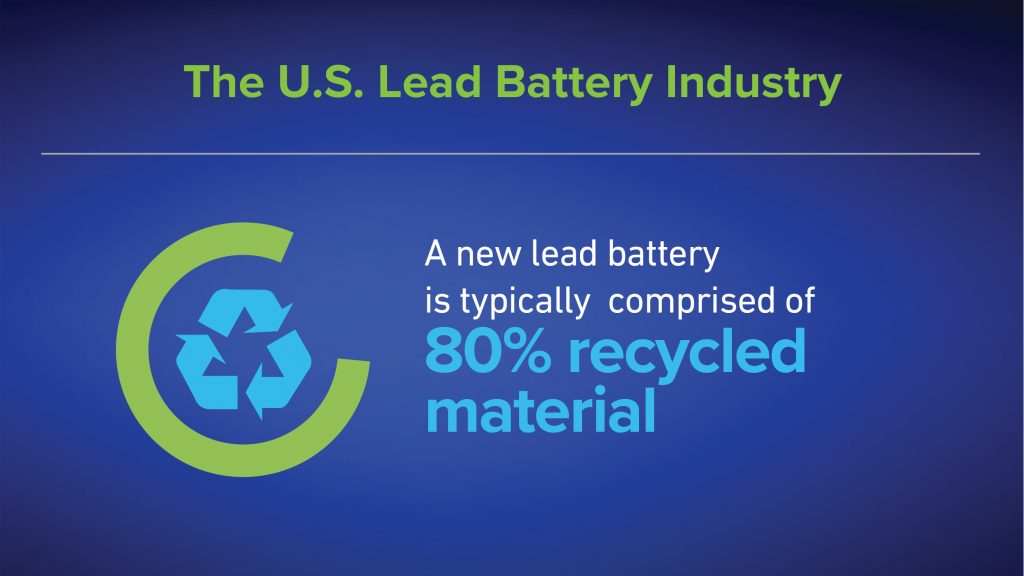

Most consumers don’t realize that the battery powering their vehicle today is likely composed of materials that have been recycled multiple times. In fact, 80% of a typical new lead battery consists of recycled materials, making it one of the most resource-efficient products in the modern economy.

A model for domestic supply chain resilience

The lead battery industry’s recycling success story goes beyond environmental benefits. With over 300,000 collection sites nationwide and a robust network of domestic recycling facilities, the industry has created a resilient, self-sustaining supply chain that:

- Supports more than 121,000 American jobs

- Contributes nearly $33 billion to the U.S. economy

- Sources 83% of needed materials from North American recyclers

- Operates 39 manufacturing facilities and 10 recycling centers across the U.S.

Innovation meets sustainability

Today’s battery manufacturing process showcases how traditional industries can embrace modern environmental standards. Through technological advancements and an unwavering commitment to sustainability, manufacturers have revolutionized their production methods.

The industry has achieved remarkable reductions in greenhouse gas emissions by manufacturing batteries with recycled lead instead of mining new lead, resulting in a 90% decrease in emissions. Many facilities are now approaching zero-waste targets while continuously improving performance and longevity.

Setting Standards for Future Industries

The lead battery industry stands as a compelling example of how sectors can successfully transition to a circular economy, offering valuable insights for other industries seeking to reduce their environmental impact. At the core of this achievement lies a foundational commitment to designing products with their end-of-life in mind. Manufacturers incorporate recyclability into their product development process and carefully select materials that can be efficiently dismantled and repurposed. This forward-thinking approach, coupled with substantial investment in domestic recycling infrastructure, has created a robust network of collection points and processing facilities that efficiently manage end-of-life batteries.

What truly distinguishes the battery industry’s success is the powerful combination of industry-wide commitment to sustainability goals and strong partnerships between stakeholders. Rather than working in isolation, companies across the value chain have aligned their objectives. Manufacturers collaborate closely with retailers and recyclers to implement effective take-back programs and ensure recycled materials meet quality standards. These partnerships have not only created efficient reverse logistics systems but have also demonstrated that with proper design, infrastructure, and cooperation, creating a viable circular economy is not just an environmental imperative but a sound business strategy.

BCI members driving sustainable innovation

The battery industry’s commitment to sustainability is exemplified through the innovative practices of BCI’s member companies. In 2021, Crown Battery became the first U.S. battery manufacturer to power its operations with 100% renewable energy, earning recognition as an EPA Green Power Partner. Their transition to solar and wind energy saved more than 56 million kWh of electricity – enough to power over 5,100 homes.

Gopher Resource demonstrates the power of recycling at scale, keeping more than 22 million lead batteries from landfills annually through its facilities in Minnesota and Tampa, Florida. The company processes nearly 600 million pounds of lead and 40 million pounds of polypropylene into pellets for reuse each year, contributing significantly to the industry’s circular economy.

East Penn Manufacturing showcases the impressive efficiency of modern recycling operations, processing approximately 30,000 batteries daily. Their commitment has earned them the highest UL Recycled Content Validation for batteries in the world, with 98% recycled material in their transportation batteries.

Hammond Group champions innovation through their state-of-the-art research facility in Indiana, which drives advancements in lead battery technology while developing manufacturing efficiencies that reduce energy consumption. Similarly, ENTEK International demonstrates exceptional material efficiency, achieving a 99.9% recycling rate of raw materials in their separator production.

Recent achievements by EnerSys highlight the industry’s progress in environmental stewardship, including a 25% reduction in direct greenhouse gas emissions in 2023 compared to 2019, and nearly 10% reduction in water usage from 2022 to 2023. Stryten Energy exemplifies modern manufacturing sustainability, producing batteries with 90% recycled material, and for every battery produced, Stryten recycles the equivalent of that battery through its North American-based recycling partners.

The next chapter in recycling excellence

As we observe America Recycles Day 2024, the battery industry isn’t resting on its laurels. Continued investment in research and development aims to push the boundaries of recycling efficiency while further reducing environmental impact. The industry remains focused on enhancing battery performance and strengthening domestic supply chains, ensuring its position as a leader in sustainable manufacturing.

The lead battery industry’s recycling success demonstrates what’s possible when manufacturers, retailers, and consumers work together toward sustainability goals. On America Recycles Day, let’s recognize this achievement while remembering that true sustainability requires ongoing commitment and innovation.

The battery industry proves that 100% recyclability isn’t just an ambitious goal – it’s an achievable reality. As we face growing environmental challenges, this industry’s circular economy model offers hope and direction for a more sustainable future.