Timing of Announcement Coincides with Climate Week NYC, Sept. 17–24

Climate change and the need to achieve zero emissions takes center stage during 2023 Climate Week NYC, held September 17–24. The annual event is the largest of its kind, organized in partnership with the United Nations General Assembly and the City of New York.

With the theme “We Can. We Will,” this year’s program is sure to have a heightened focus on reducing emissions. The battery industry is echoing that concern with concrete, new information on its role in reducing emissions in transportation.

Lead Batteries Increase Sustainability Profile of EVs and Hybrids

Electric vehicles (EVs) are at the forefront of discussions to create greener transportation. A new study sponsored by Battery Council International and the International Lead Association is reinforcing why batteries should be a central part of those conversations.

The recently released study and research brief provide a lifecycle assessment (LCA) of two primary automotive battery chemistries, with surprising findings:

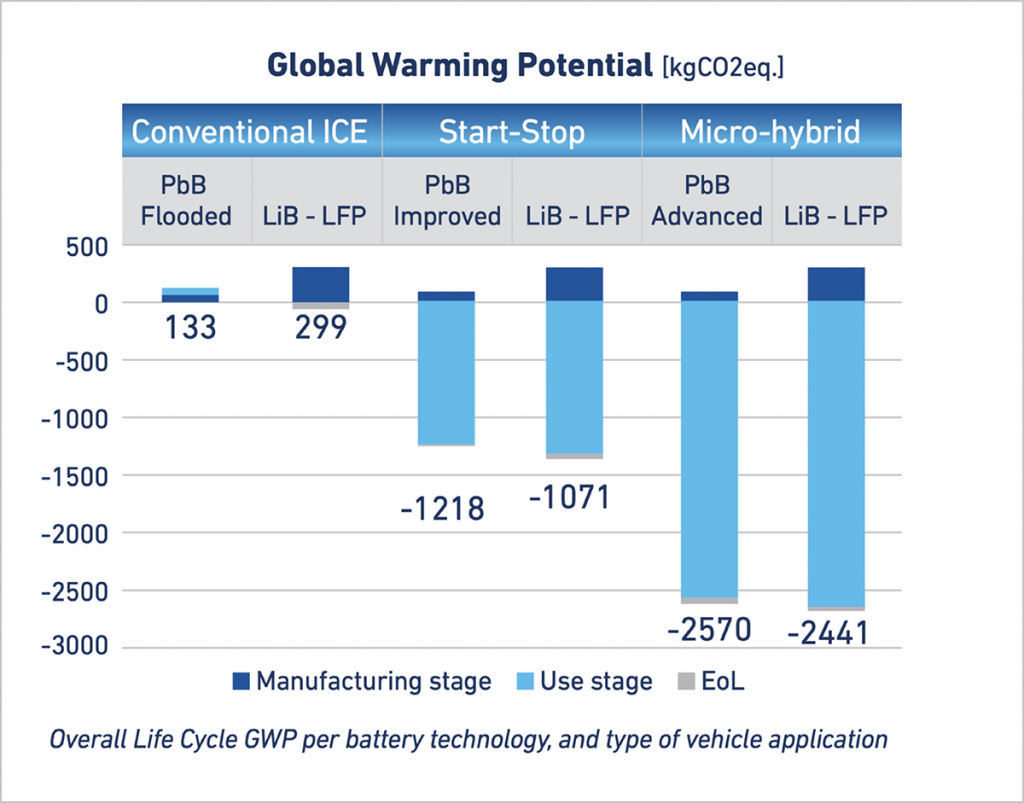

- The environmental impact of manufacturing a lead battery is four times less than manufacturing a similar lithium-iron phosphate (LFP) battery.

- Lead batteries were shown to have a lower Global Warming Potential (GWP) impact than lithium-iron phosphate batteries, under the assumptions taken in the baseline scenario of the study. GWP is the most used metric for quantifying the ability of each greenhouse gas to trap heat in the atmosphere.

Furthermore, a previous, unrelated study found that recycling lead produces 99% less CO2 emissions per 100,000 tons of metal produced, compared to virgin ore.*

A Recycling Success Story: Lead Batteries

The recycling impact contributed greatly to the outcome of the study results. Lead is the most efficiently recycled commodity metal, and lead batteries are the only battery system that’s almost completely recycled, making them a model circular economy. The industry’s well-established recycling infrastructure results in a 99% recycling rate. Additionally, the design of lead batteries – they share the same basic chemistry and have minimal components – contributes to the ease of recycling,

In contrast, today’s LFP batteries only use primary materials, including lithium carbonate and phosphorus, as well as electronics that use precious metals (which are recovered). There are challenges in recycling lithium battery waste, a process that is in its infancy.

In fact, lithium-ion batteries have an estimated 15% collection rate and a 5% recycling rate. Currently only the passive components, as well as electronics and the battery case, are recycled, while the cell itself is incinerated. Also, though lithium batteries share several common features, there is wide variation in the active materials and componentry, which makes them more difficult to recycle.

Lead Battery Industry Turning “We Can. We Will” into “We Are”

The lead battery industry is committed to help mitigate climate change by using sustainable manufacturing processes. As the new study shows, it has become essential for auto manufacturers to consider a battery’s sustainable manufacturing profile when selecting battery chemistries. It’s another important step toward reducing carbon emissions.

About the New Study

The goal of the study, called “Comparative LCA of Lead and LFP Batteries for Automotive Applications,” was to assess the environmental profile of two different batteries used in the automotive sector: The cradle-to-grave environmental impact of a lead-based (Pb) automotive battery and a lithium-iron phosphate (LFP) automotive battery within North America.

The study was conducted by Sphera Solutions, Inc. according to ISO 14040/44, the international standards on lifecycle assessment (LCA). Battery Council International and the International Lead Association commissioned the study to better understand the environmental impact of 12V lead-based battery production and promote continuous improvement in the environmental sustainability of lead batteries.

*Report on the Environmental Benefits of Recycling, Bureau of International Recycling, 2008, Page 43.