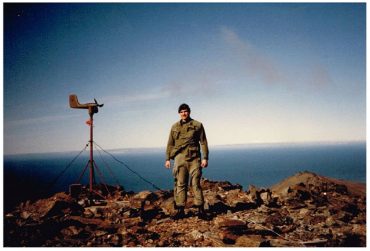

Meet Zach Beugli with ENTEK International, a Battery Council International (BCI) Member Company

The funding is meant to expand domestic manufacturing of batteries for electric vehicles and the electrical grid, and for materials and components currently imported from other countries. But multinational ENTEK is notable for another, more personal reason, which we celebrate on Veterans Day, November 11.

ENTEK Shows Appreciation for Employees Who Are Veterans

The Battery Council International member company has a long tradition of hiring from the various U.S. military services. The company currently employs nearly 50 veterans of the armed services between the Lebanon, Oregon, global headquarters and a new manufacturing facility in Henderson, Nevada.

Each year, ENTEK honors the employees who have proudly served by hosting a lunch across all shifts and positions. It’s just one small way the company shows appreciation for those who sacrificed for their country and are shining examples of ENTEK’s core values. Zach Beugli, ENTEK safety technician, is one such example.

Employee Zach Beugli Brings Military Mindset and Work Ethic to ENTEK

Zach is a veteran of the U. S. Army and the second generation of his family to serve in the Army, following in his father’s footsteps. Zach joined the Army at 19, hoping to find a career path while serving his country. After being a military mechanic for three years, he reclassified as a medic for another three years. He also served a year in Iraq.

Zach was kind enough to answer our questions about his military service and working at ENTEK.

Do you think your service in the military has benefitted ENTEK?

“Absolutely. The Army definitely taught me how to be more responsible, more focused, and [it] helped me develop skills to manage time in a productive way.

“Those things transferred over to ENTEK in a huge way. Starting out as a production operator and working with our continuous process, those tools I learned in the service come into use every day.

“And now, as a safety tech here at ENTEK, [my] last four years’ experience as a medic in the Army has certainly benefitted me in how I do my job at ENTEK.”

How did serving as a medic help in your job within ENTEK’s Safety Department?

“Well, safety is definitely our first priority at ENTEK, and with my experience as a medic in the military, I definitely had to have the mindset of planning for the worst. We called it the ‘What if? Game.’ We would think of the most ridiculous thing that could happen, and plan for that.

“In my position now, that experience definitely helps me weigh the risks for each process and project at ENTEK and understand how to address those risks.”

What are some of challenges you face as a safety tech for ENTEK?

“The biggest thing is that ENTEK is really three different companies – manufacturing and two different types of production, all in one campus. So it becomes challenging to plan specifically for each of those companies and know the process in each of those areas. It certainly can keep me on my toes – something else serving in the military taught me.”

The Lead Battery Industry Thanks All Veterans

Thank you, Zach! Our industry couldn’t be more grateful for the valuable presence of veterans within the lead battery manufacturing and lead battery recycling sector. They bring incredible skills and leadership to their civilian jobs throughout our highly sustainable industry.

About ENTEK

ENTEK has over 35 years of experience producing battery separators for batteries to support electric, advanced start-stop and standard vehicles, trucks, emergency vehicles, emergency backup power, utility scale energy storage, and industrial batteries. ENTEK is also a vertically integrated designer and manufacturer of extruders and material handling equipment for the production of battery separators.