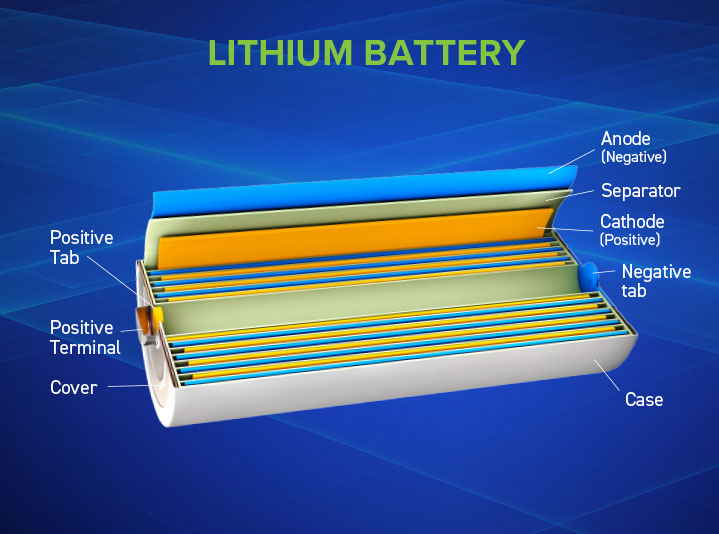

Lithium-ion batteries offer transformative benefits for modern industries. These batteries are known for their high energy density, relative light weight, and excellent performance. Their compact size and fast charging capabilities make lithium batteries well-suited to specific applications.

Top Energy Storage Execs Reflect on EVs, China,...

Leading executives agree that the energy storage landscape is entering one of the most formative periods in its history and also agree that...

Article

May 13, 2024