Panel Discussion During National Clean Energy Week Includes Supply Chain and Metals Expert from East Penn Manufacturing

NOTE: This is the second of two blogs devoted to NCEW 2022. Read the first blog here.

Lead batteries and, in particular, their domestic circular economy, were a key topic during a September 27th virtual symposium titled, “Clean Energy Transition Requirements: Critical Minerals, Supply Chains and Domestic Manufacturing.”

The six-member panel discussion was held as part of the 6th Annual National Clean Energy Week (September 26–30). Panelists included Jordan Geist, senior director of the Metals Division of East Penn Manufacturing Company. He spoke in detail on lead battery recycling and the secure lead battery supply chain. The company is the largest, single-site privately held lead battery manufacturer in the world.

During the session, the group explored many major issues affecting the clean energy transition using technologies like EVs and renewable energy.

![Geist Headshot[20] Jordan Geist East Penn](https://batterycouncil.org/wp-content/uploads/2022/09/Geist-Headshot20-346x370.jpg)

This blog highlights conversations held around sustainability, including how the domestic lead battery industry avoids supply chain disruptions and protects national energy security by using a circular economy and being one of the most sustainable battery technologies available today.

Panelists Agree on Top Concerns for Advancing Clean Energy

The group had consensus on several key points up front:

- We all want an energy system that’s affordable, reliable, clean and secure.

- We must address supply chain issues around critical minerals.

- Meeting clean energy needs will require a mix of energy storage technologies.

Reliance on Foreign Supply Chains Increases U.S. Vulnerability

Energy security was a key topic during the hour-long discussion.

“Energy security is one of the most important things our generation and future generations are going to need to protect,” said panelist Samantha Sloan with First Solar, Inc. “When we have an overall dependency on an adversarial nation, we lose control of supply chain security.”

Dan Blondal, CEO of Nano One Materials Corp, said critical minerals are the “linchpin of our clean energy future.” Many battery technologies, such as lithium-ion batteries, require critical minerals that are in scarce supply. He added that market demand for lithium, nickel, cobalt and graphite are projected to rise by 20 to 40 times in the coming decades. It’s further complicated by geopolitics.

“A good chunk of the world’s lithium goes through Russian to be converted into lithium hydroxide. Because we don’t have those facilities here, it creates a bottleneck. Same thing goes with nickel and Russia,” said Blondal.

Lead Batteries Use Circularity to Ensure Strong Domestic Supply Chain

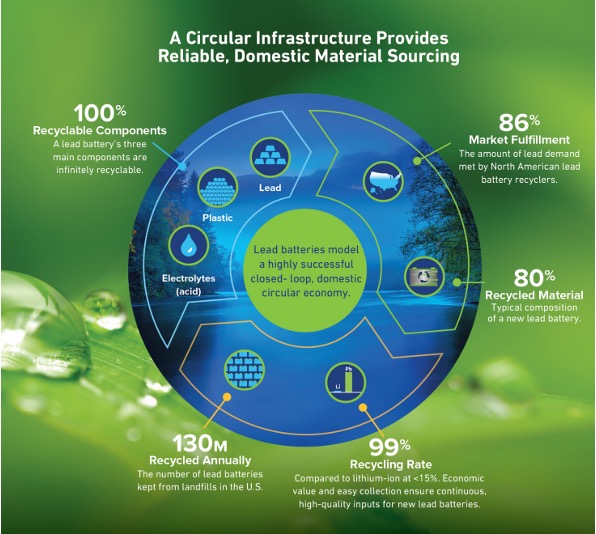

In contrast, Geist explained how lead battery manufacturers like East Penn source close to 90% of major raw materials, including lead, domestically. That greatly benefits national security and the environment.

“There is no other product in the world that you can manufacture, and at the end of its life, recycle 99% of it to make a new product. We’re not talking cradle-to-grave here. We are literally talking about a true circular economy, cradle-to-cradle.”

He shared how the North American lead battery industry already has established infrastructure to manufacture, collect, recycle and remanufacture lead batteries. That ensures feedstock for new lead batteries remains available and protected from global disruptions. And, he said, lead batteries have multiple applications beyond clean energy applications, powering everything from vehicles, to forklifts, wheelchairs, energy storage and backup power for the grid, communication and data centers and much more.

Battery Recycling Keeps Critical Minerals on Domestic Soil

Geist stressed how battery recycling will continue to be a critical component in securing our domestic supply chains. Lead battery recycling is already preventing materials from going overseas.

“We need to take advantage of the established infrastructure in place today and scale as fast as we can to create an environment for safe, environmentally sound recycling practices domestically.” If not, said Geist, precious critical minerals will go to countries like China.

Not all battery technologies are prepared, Blondal replied. “Recycling is always going to be incredibly important for lithium-ion batteries, as well, but we’re a long way off [from achieving that]. We’re in the infancy with lithium batteries. We don’t have a critical mass yet, so we’re 20 to 30 years away from having a really complete circular economy for lithium batteries.”

Sloan weighed in, “Today, half of the world’s copper refining happens in China. We need to take Jordan’s story line and think about the sustainability and circularity all the way back to mining, and what we can recover in tailings.”

U.S. Recycling Methods Safer, More Sustainable

Geist proposed applying lead battery’s circularity mindset, and especially the lead battery industry’s stringent recycling process, to all new technologies.

“Most of the time, [critical] minerals are recycled in countries with less-than-desirable recycling practices, creating further adverse environmental and social problems.”

Blondal shared Geist’s thinking. “We need to retarget raw material supplies that are in existence today in North America.” He discussed the dangers of battery byproducts going into landfills or the ocean. “We simply cannot tolerate the volumes of waste that are produced in the supply chain. It’s imperative to change it, from…the way it’s done in Asia.”

“Marshalling Our Resources” to Control Our Clean Energy Destiny

Alex Fitzsimmons, senior director with ClearPath, summed up the next steps needed.

“We need to marshal all of the resources that we now have in law and in policy toward three primary goals. Investing in upstream mining and processing capabilities, in reuse and recycling technologies, and in substitutes to critical minerals.”

Geist concluded by saying the U.S. is behind in sourcing raw materials domestically and creating the infrastructure and manufacturing capabilities to support our energy needs for the future. But he feels strongly that the North American lead battery industry is positioning well to be one of the many energy storage technologies needed to accelerate the clean energy transition.

“We have an abundance of innovative, advanced battery products in the pipeline and a robust, ready-to-scale infrastructure to meet our clean energy needs. That’s a win for all of us.”

Watch the full panel discussion here.