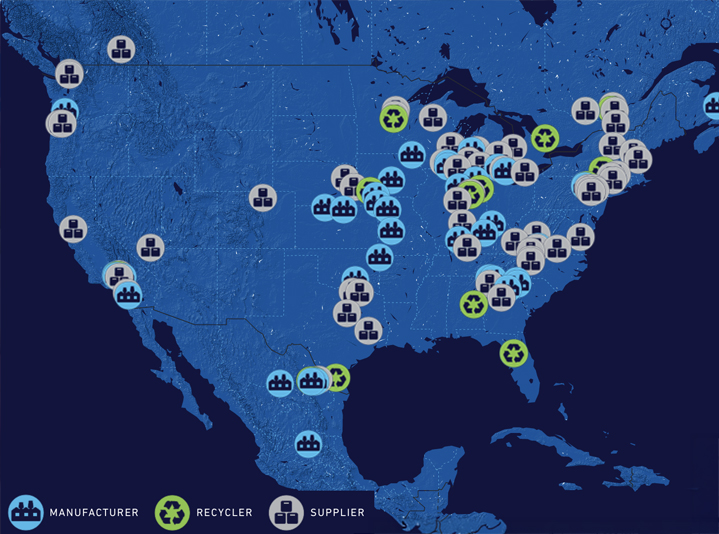

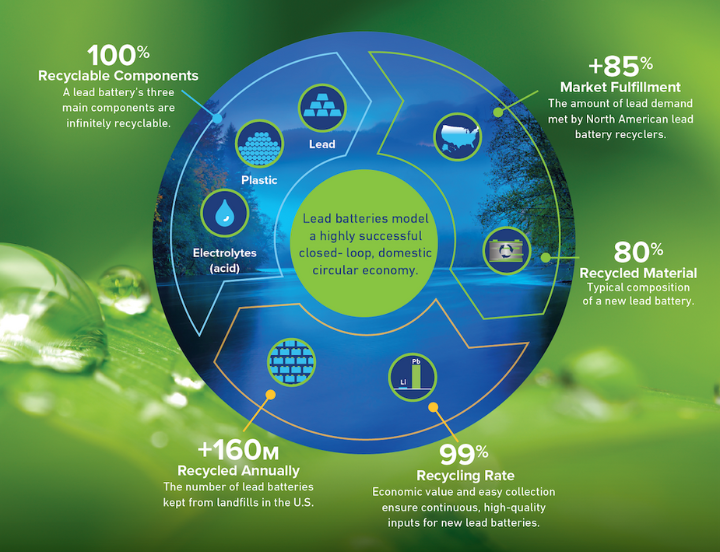

A resilient North American battery supply chain is critical to national security, economic strength, and infrastructure reliability. As global disruptions highlight the risks of foreign dependence, domestic manufacturing, recycling, and materials processing ensure the U.S. has secure access to the energy storage technologies it needs.

Manufacturing

Battery manufacturing is essential to powering the future of energy storage, transportation, and technology. The battery industry is...