Tractor cultivating a field, courtesy of Association of Equipment Manufacturers.

March 23rd is National Ag Day across the U.S. It’s a day to recognize – and celebrate – the contribution of agriculture to our everyday lives. Agriculture provides almost everything we eat, use and wear on a daily basis. The lead battery industry is proud to be the power behind the more than 2 million farm families who grow the food and fiber that keep us fed and clothed.

The Power Behind the Farmer

Millions of pieces of mechanized farm equipment run on lead batteries. The most recent USDA Census of Agriculture reports over 340,000 combines and nearly 4,400,000 tractors. And that’s just the beginning of where you’ll find lead batteries on the farm.

In addition to tractors and combines used to produce, manage and harvest row crops, you’ll find lead batteries used to power livestock feeding systems, open automatic fence gates, and provide backup power for dairy equipment. And that doesn’t even begin to count the lead batteries that power the trucks, barges, trains and other vehicles used to transport crops to market and ultimately to the grocer.

Lead Batteries Make Farmers More Productive

The mechanization of farming in the 20th century led to big changes in agriculture. Tractors, combines, harvesters and other farm machines help each farm produce more, and allows fewer people to farm more land. In the 1930s one American farmer produced enough agricultural product to feed a total of four people; today each American farmer feeds more than 165 people due to a combination of battery powered machinery and improved seeds and other crop practices. Farmers are proud to not only feed their families and fellow Americans, but to produce crops to export to the rest of the world – often on container ships that operate on lead batteries.

A Shared Goal: Sustainability

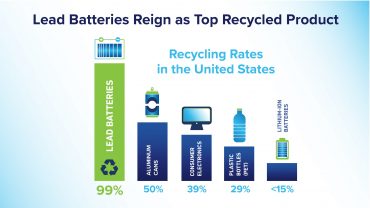

Farmers are often referred to as the first environmentalists because they are entrusted to nurture the land that provides their livelihood. They incorporate practices like no-till, which help to preserve moisture and nutrients in the soil. The lead batteries that power their equipment are part of the most successful circular and sustainable economy in the world.

99% of all used batteries, whether from a pickup truck, tractor or combine, are recycled. Lead battery manufacturers and recyclers capture the used lead, plastic and electrolytes and recycle and reuse them to make new batteries. By recycling and reusing lead from batteries, 73% of U.S. lead demand for batteries is made by U.S. lead battery recycling, reducing the need for mining and imports. Lead is infinitely recyclable, and a new lead battery is typically comprised of 80% recycled material. That means it’s possible that a farmer of today has a tractor running on a lead battery “descended” from his or hers grandfather’s tractor!

Reduce, Reuse and Recycle

Recycled lead batteries can be used again and again to power virtually any type of agricultural equipment that needs batteries. However, sustainability and innovative reuse doesn’t just stop there. East Penn Manufacturing, a leading battery manufacturer and recycler headquartered in Lyon Station, Penn., extends the meaning of Reduce, Reuse, and Recycle even further.

Through an innovative process, they capture recycling byproducts that might otherwise be neutralized, and instead reprocess them into a liquid nitrogen sulfur solution that is stored in large tanks. Thousands of tons of this solution are sold each year to agricultural fertilizer manufacturers for use as a raw material to help farmers keep their crops growing. What a great way to take a byproduct and turn it into a useful product that supports the agricultural industry.