A Sustainability Star: Lead Batteries Maintain Impressive 99% Recycling Rate

As we celebrate America Recycles Day 2023 on November 15, it’s important to highlight the remarkable sustainability achievements of the lead battery industry.

With a recycling rate of 99%, lead batteries are the most recycled consumer product in the U.S., according to the National Recycling Rate Study released this year by Battery Council International. And there’s more (or much less, depending on how you view it.) The lead battery industry’s modern, closed-loop recycling in the U.S. diverts an astonishing 160 million lead batteries from landfills annually.

These accomplishments are a testament to the lead battery industry’s commitment to environmental responsibility through responsible materials management. Here’s how lead batteries are leading the charge toward a more sustainable and circular economy.

A Multigenerational Lead Battery? Absolutely.

Though often hidden under the hoods of our vehicles or behind the scenes in battery banks, lead batteries have silently become the unsung heroes of recycling, embodying the principles of “use-recycle-remanufacture.”

Did you know that a typical new lead battery comprises 80% recycled material from spent or used lead batteries, including their lead, plastic and, sometimes, the electrolyte? The reason is simple: the lead in lead batteries can be infinitely recycled without any loss in quality or performance. This means that the lead from a battery in your car today may find its way into the battery of your grandkid’s future hybrid or electric vehicle.

Driven by Successful Circular Economy

Lead batteries exemplify a successful circular economy. It begins with a lead battery being designed for recycling. In fact, lead batteries have earned the title of the most recycled consumer product in America, according to the U.S. Environmental Protection Agency.

At the end of their life cycle, lead batteries are carefully disassembled and separated into three key components, all of which are 100% recyclable: lead, plastic and acid. These components are then transformed into valuable raw materials needed by U.S. manufacturers to create new lead batteries, continuing the cycle of use-recycle-remanufacture.

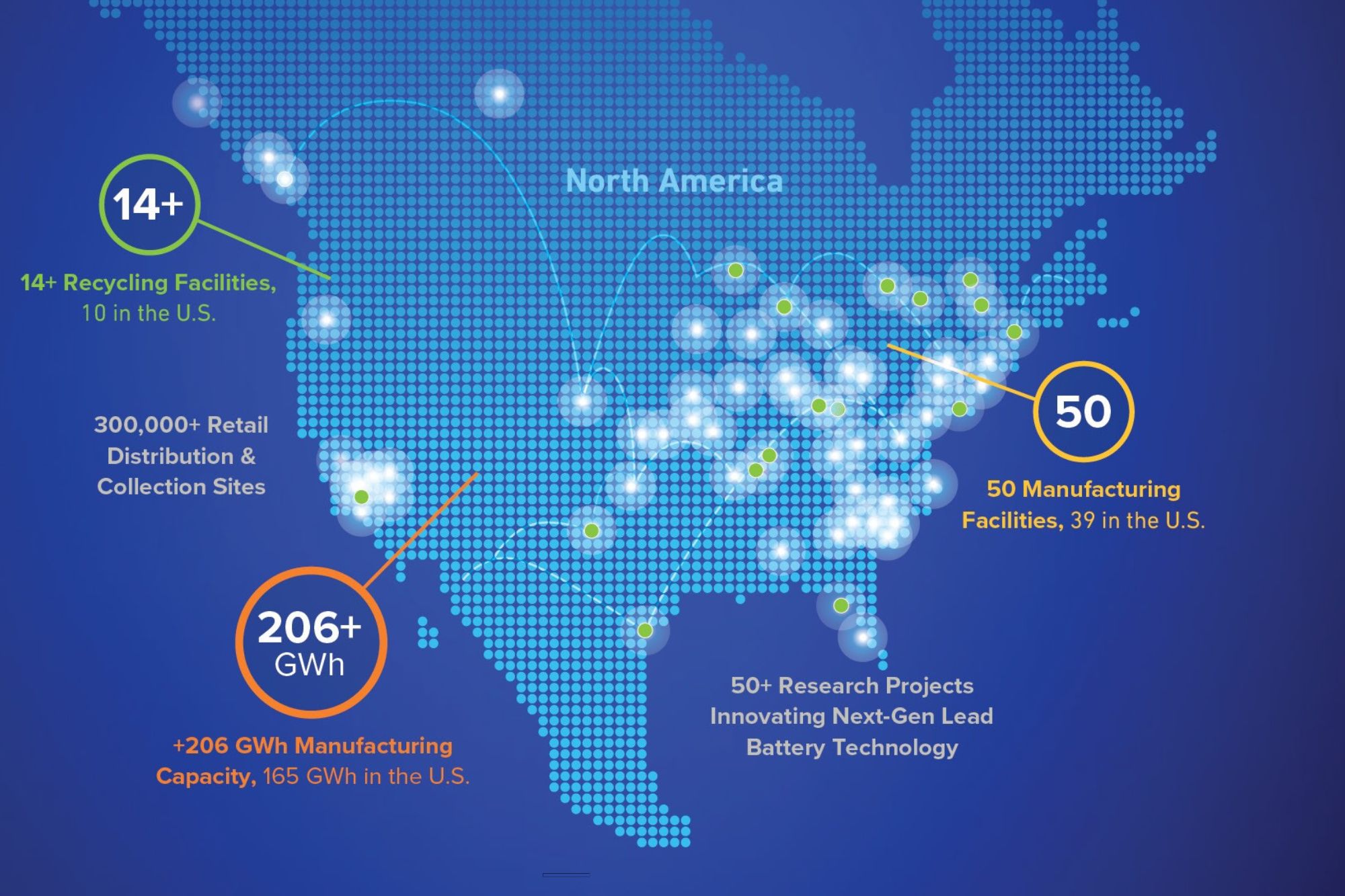

Supported by Coast-to-Coast Lead Battery Infrastructure

In contrast to some newer battery technologies, lead batteries benefit from an established coast-to-coast network of manufacturing, collection and recycling facilities across North America. This infrastructure not only fosters sustainability, it ensures a reliable domestic supply chain for lead battery manufacturers. The system’s efficiency is a significant driver behind the remarkable recycling success of lead batteries.

Consider the most recent statistics on the North American lead battery industry’s domestic infrastructure. There are:

- +206 GWh lead battery manufacturing capacity, +165 GWh in the U.S.

- 50 lead battery manufacturing facilities, 39 in the U.S.

- 14+ recycling facilities, 10 in the U.S.

- 300,000+ retail distribution and collection sites for used batteries

Environmental, Economic and National Security Benefits

The collective efforts of the lead battery industry have far-reaching positive impacts on the environment, economy and national security. Here are some of the direct benefits of diverting 160 million lead batteries from landfills into the recycling process:

- Environmental Benefits: Recycling reduces the need for mining new raw materials and minimizes the environmental impact associated with it. Today, in their goal to achieve near zero waste, modern lead battery manufacturers produce new batteries with 90% less energy and 90% less greenhouse gas emissions, thanks to recycling.

- Economic Benefits: The lead battery industry directly employs more than 38,000 workers who build and recycle batteries in America, contributing $33 billion to the national economy.

- National Security Benefits: Today, U.S. lead battery manufacturers source more than 83% of the needed lead from North American battery recyclers. This secure domestic supply of recycling inputs reduces international supply chain disruptions and reliance on foreign suppliers.

Promoting Sustainable, Secure Energy Future

The lead battery industry has been pioneering sustainability efforts for over a century, and it’s not slowing down. Lead batteries are integral to the nation’s transition to clean energy storage and a low-carbon future. The industry will continue to set a high bar for circularity, advancing recycling technologies, and showcasing the potential for a brighter, more eco-friendly future.

As we celebrate America Recycles Day, let’s recognize the lead battery industry’s unwavering commitment to recycling and sustainability. It’s practices have established a model closed-loop circular economy that other industries can emulate.