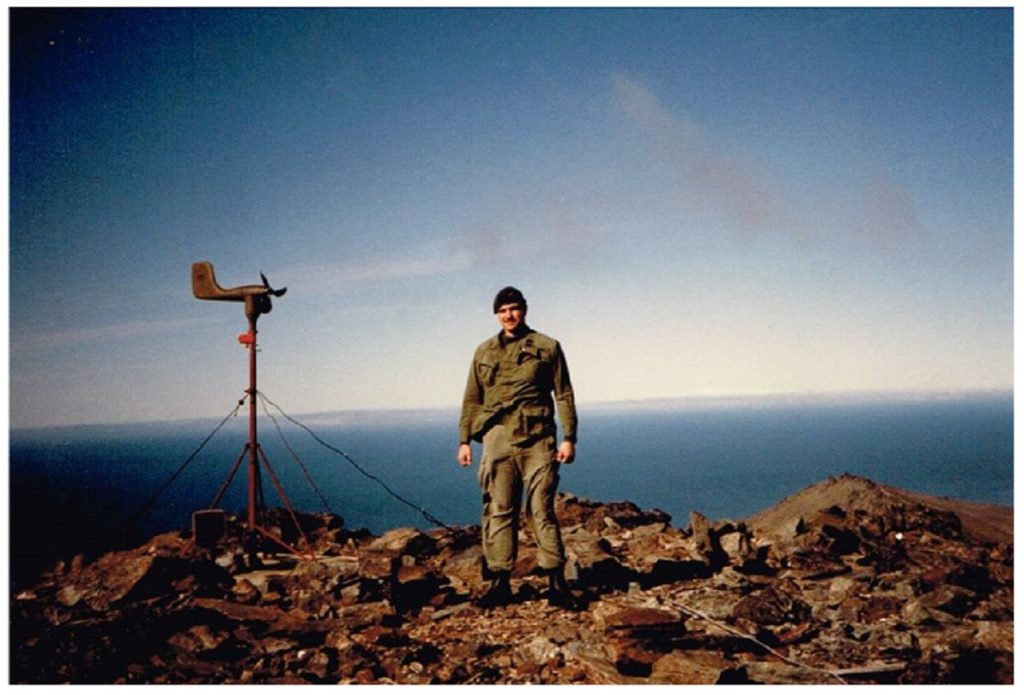

U.S. Army Staff Sargent Kevin Moran in Alaska with Russia in the background.

U.S. Army Staff Sargent Kevin Moran in Alaska with Russia in the background.To show our great appreciation for veterans, we’ve been highlighting some who work in the lead battery recycling industry. For this blog, the last in our three-part series, we profile a fine example in our own office, Kevin M. Moran, the executive vice president of Battery Council International (BCI).

Below is our Q&A with Moran, who advocates for all members of BCI. It is the not-for-profit trade association that represents companies worldwide engaged in every facet of the industry: lead battery manufacturers and recyclers, marketers and retailers, suppliers of raw materials and equipment, and expert consultants. As the industry’s principle association, BCI’s member have a global impact.

Moran serves BCI’s diverse membership, just as he once served his country. We spent some time with him to better understand his military service and how he supports the lead battery recycling industry.

What branch of military did you serve in? “I proudly served as an enlisted soldier in the U.S. Army from 1980–1985, and in the Active Reserves from 1985–1988. I attained the rank of staff sergeant. My final active duty assignment was with Task Force 160, which is now designated the 160th Special Operations Aviation Regiment (Night Stalkers). The 160th provides aviation support for the broader special operations community.”

What is your current job? “I serve as the executive vice president of Battery Council International, the North American trade association representing the lead-based manufacturing, supply, recycling and distribution companies. Our mission is to promote the responsible use of lead batteries for all energy storage applications, as well as to represent the industry on environmental, health, safety, economic and other governmental policy issues.

“Lead batteries have been around for 160 years and BCI for nearly 100. But our members continue to invest in research and development to improve the capacity of lead batteries and to protect the environment, our workers, and the public.”

What have you learned about recycling that you’d like others to know? “The lead battery industry’s commitment to efficient recycling methods ensures that lead batteries are an essential part of an energy storage mix to achieve a cleaner, greener future.

What have you learned about recycling that you’d like others to know? “The lead battery industry’s commitment to efficient recycling methods ensures that lead batteries are an essential part of an energy storage mix to achieve a cleaner, greener future.

“Lead batteries have a recycling rate of 99%, compared to the fewer than 5% recycling rate of lithium-ion batteries. In fact, lead batteries are the most recycled consumer product in the U.S. This makes the lead battery industry a leader in creating a circular economy and a model for other battery chemistries – and industries – in how to responsibly design, make, use, recycle and remanufacture materials.”

Can you say more about a circular economy? “Lead batteries are safely manufactured and recycled through a state-of-the-art ‘closed-loop’ process that keeps more than 129 million lead batteries out of U.S. landfills annually. During the recycling process, the battery is broken down into its primary components for reuse: lead – which can be infinitely recycled with no loss of performance – plastic and acid. On average, a new lead battery is comprised of more than 80% recycled material.

“Our industry’s process has been recognized by the World Economic Forum and MIT’s Center for Transportation and Logistics as the world’s most successful example of a circular economy.”

How does the industry achieve a 99% recycling rate? “A nation-wide infrastructure, high recycling awareness and the economic value inherent in lead battery components ensures consumers and industries return spent lead batteries to the collection system, which, in turn, supplies manufacturers with a reliable stream of materials for reuse.”

How does recycling create job opportunities? “The lead battery industry is thriving. For 2018, it reported nearly 25,000 direct jobs in 38 states, which is a 20% increase in reported direct jobs since 2016. Nearly 15% of these jobs are exclusively in lead battery recycling.

“These are manufacturing jobs and, compared to other private sector jobs, the average salaries are 96% higher for recycling and mining workers and 28% higher for manufacturing workers. Additionally, a high percentage of occupations are available to workers who have a high school diploma or equivalent, providing a pathway to the middle class.”

What sort of economic impact does those jobs make? “In 2018, the lead battery industry paid $1.7 billion in wages and spent more than $100 million in research and development. Many of the top occupations in the lead battery industry have a high share of green jobs, compared with other sectors of the economy, because the industry generates an environmental benefit by diverting materials from landfills and re-using those materials in a circular economy model.”

Any parting words? “I would like to especially thank all of the military veterans who work in the lead battery industry. We value the tremendous skills you bring to the workplace every day.”

We thank Kevin and each of the veterans who shared their stories in this three-part blog series!

Learn More

Battery Council International

EPA America Recycles

Video: How a Lead Battery Is Recycled

Essential Energy Everyday Recycling

EPA Success Stories in Recycling

News Release: Lead Battery Industry Partners with EPA to Celebrate #VETSRECYCLE