Photo courtesy of Crown Battery Manufacturing Company

Industry’s Circular Economy Fosters a More Resilient, Secure Energy Future

Note: This is the first of a series of blogs throughout October related to Manufacturing Day 2022. The posts also launch our exciting Essential Energy Tour. Stay tuned as we report on virtual and in-person visits to some of the most innovative companies advancing the lead battery industry.

A key finding in a recent survey of U.S. manufacturers found that 78% of manufacturing leaders listed supply chain disruptions as a primary business challenge. Only 11% believed improvement will occur by year’s end.

In contrast, the U.S. lead battery manufacturing and recycling industry is happy to report its resilience against such disruptions. As we approach Manufacturing Day (MFG Day) 2022 on October 7, the lead battery industry is highlighting its vast North American infrastructure and proven circular model. Its closed loop manufacturing system ensures a strong domestic supply chain is available to create cleaner energy storage and a more secure energy future.

Lead Battery Industry Shares Success Story

In conjunction with this year’s MFG Day, we’re examining the factors behind the reliability and resilience of the lead battery manufacturing and recycling industry. We’re also sharing details on its robust U.S. economic impact that stems from lead batteries providing 60% of the world’s rechargeable power. The U.S. lead battery industry:

- Provides more than 25,000 good-paying jobs.

- Makes a $26.3 billion economic contribution to the national economy.

In the second of this blog series, we’ll share profiles of North American Battery Council International (BCI) member companies. Featuring these strong manufacturing companies is part of our “Essential Energy Tour.” [See more below.]

Lead Batteries Ready to Meet Growing Demand for Energy Storage

Wind, solar and battery storage represent 81% of all new power additions across all energy types in 2021, according to American Clean Power. In fact, the clean power project pipeline grew to 128 GW, representing over $145 billion in new investment in that same period.

That growth reflects the increasing demand for energy storage cited by the U.S. Energy Information Administration. It also predicts that global energy consumption will increase nearly 50% over the next 30 years, with renewable energy rivaling fossil fuels. Maximizing renewables will require a mix of renewable energy storage solutions, including lead batteries that have key environmental and economic benefits.

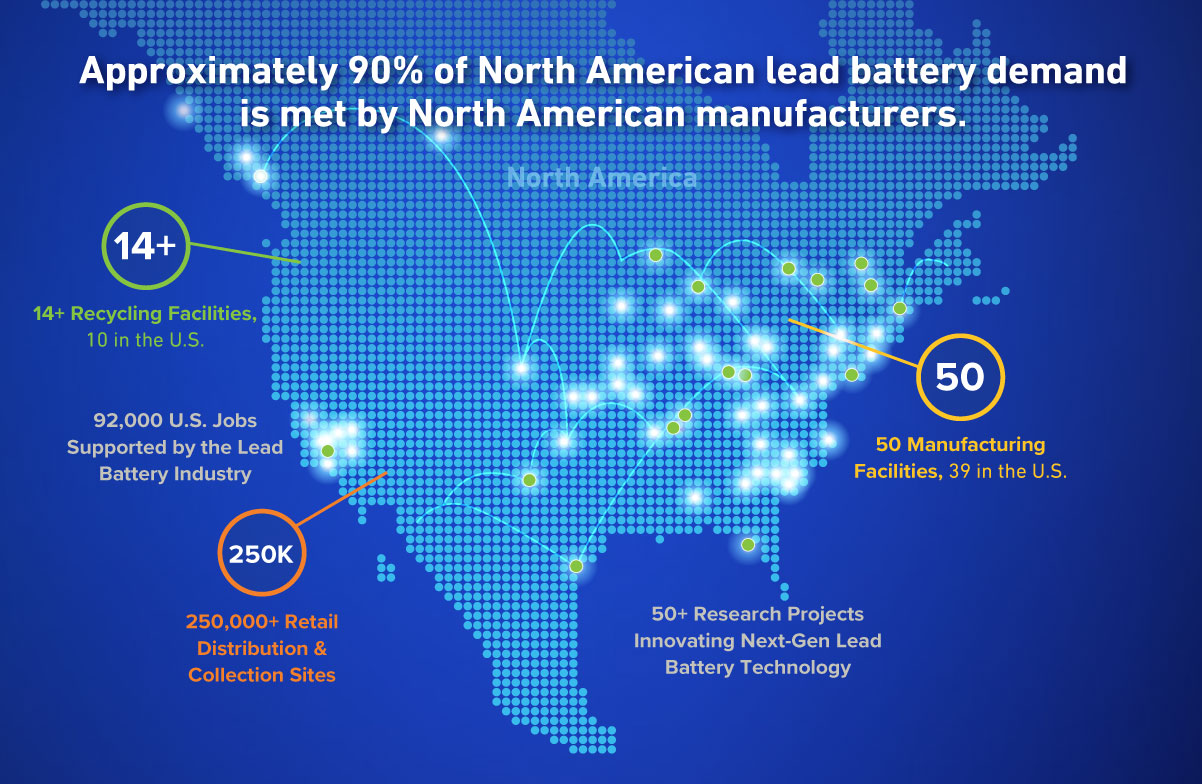

Strong Lead Battery Manufacturing Model Known for Resiliency, Reliability

The lead battery industry has an established North American network to manufacture, collect, recycle (lead batteries have a 99% U.S. recycling rate) and remanufacture lead batteries:

- 50 lead battery manufacturing facilities (39 in the U.S.)

- More than 250,000 lead battery collection and distribution sites in the U.S.

- 14+ lead battery recycling facilities (10 in the U.S.)

This model of a true circular economy is essential to companies who manufacture new lead batteries. They rely on the industry’s closed-loop economy for a consistent supply of high-quality, cost-stable inputs – especially recycled lead, which is infinitely recyclable. This proven manufacturing model helps to inoculate the industry to supply chain disruptions. In turn, that helps to further ensure our country’s energy security.

Lead Batteries Provide High-Paying Green Jobs and Technology Training

Manufacturing Day (actually a week-long event) showcases modern manufacturing careers, as manufacturers seek to fill 4 million high-skill, high-tech and high-paying jobs over the next decade. The U.S. lead battery manufacturing and recycling industry greatly values and rewards its 25,000 employees:

- Average, per-worker salary among lead mining and recycling companies is $98,100. (This is 96% higher than other similar private industry sector salaries.)

- Average, per-worker salary among lead battery manufacturers is $64,000. (This is 28% higher than other similar private industry sector salaries.)

In addition to being appropriately compensated, the lead battery industry invests in the people working in the plants by providing technology training. Manufacturing is growing more sophisticated, and more manufacturing jobs will require employees skilled in operating digital technologies and systems, and repairing sophisticated equipment. That calls for understanding robotics, artificial intelligence and data analytics.

As manufacturers like those in the lead battery industry invest in their plants, they are also striving to advance employees’ skills to ensure they’re ready for the increasing digitization and automation of manufacturing processes.

Essential Energy Tour Spotlights U.S. Manufacturing Facilities

This fall, we’re touring (virtually and in-person) several of our U.S.-based manufacturing “super stars.” Each are part of the strong network of BCI member companies who manufacture and recycle batteries or are members who provide critical services and supplies used to create batteries. The companies comprise a vast domestic infrastructure that ensures a reliable, secure energy source to power the U.S. economy.

The Essential Energy Tour starts in Indiana with Hammond Group, Inc. Watch this space for other tour stops, as we travel across the country learning about an industry that sustainably provides 60% of the world’s rechargeable energy storage, contributes billions to the U.S. economy and is investing heavily in research to unlock the full potential of lead batteries.

On the eve of Manufacturing Day 2022, we thank everyone involved in the U.S. lead battery manufacturing and recycling industry!