Like father, like son. Jared (left) followed his father Tod’s path to enlist in the U.S. Coast Guard; Senior Chief Petty Officer Tod Lyons retired after 20 years of service.

Like father, like son. Jared (left) followed his father Tod’s path to enlist in the U.S. Coast Guard; Senior Chief Petty Officer Tod Lyons retired after 20 years of service.November is a big month for veterans and the recycling industry. In conjunction with Veterans Day (Nov. 11), America Recycles Week (Nov. 10–16) and America Recycles Day (Nov. 15), the Environmental Protection Agency (EPA) is highlighting veterans who work in recycling.

With that in mind, we asked members of Battery Council International (BCI) to provide stories of their military veteran employees that we could share with EPA. Here is the second in our three-part series.

Interstate Batteries Recycling: Employing Former U.S. Coast Guard Expert

Today, Lyons brings his valuable U.S. Coast Guard experience to Interstate Batteries Recycling.

Tod Lyons joined Interstate Batteries Recycling (IBR) more than 10 years ago. As its sustainability program manager, he educates people and businesses about lead battery sustainability and the proper handling of all types of spent batteries. He also brings two decades of active duty in the U.S. Coast Guard to his job at IBR every day.

During his service, Lyons directed and managed crisis communications activities during major operations, such as search and rescue, homeland security and drug interdiction, as well as oil spills, chemical spills and natural disasters around the Western Hemisphere.

His duty assignments included two tours with the Coast Guard’s National Strike Force who are considered experts in oil and chemical spill clean-up and environmental remediation. Lyons was also a first responder to the terrorist attacks on The World Trade Center in New York City in September 2001.

He brings his deep skillset to IBR to promote and market its sustainability through speaking opportunities, presentations and writing for industry publications. Having a strong command of environmental government regulations, he also manages projects to help IBR comply with federal environmental and transportation laws. He’s known in the greater battery industry, too. Lyons was instrumental in helping BCI create a lithium battery awareness campaign. Its focus is educating battery handlers to recognize the differences between lead batteries and lithium batteries, for the safety of all workers.

When asked what others should know about the recycling industry, Lyons had much to say.

- Circular Economy. “Lead batteries are a viable, sustainable, backup storage product that contributes to a circular economy through a closed-loop recycling process. The lead from the battery in your grandfather’s pick-up truck may very well be used in lead batteries in today’s vehicles.”

Lyons added that 99% of all lead batteries manufactured are recycled to make new lead batteries. And, that between 2016 and 2018, IBR collected more than 3 billion pounds of lead batteries for recycling. “Secondary lead recyclers are highly regulated and lead battery manufacturers are always looking for ways to improve technology to help lead batteries remain sustainable for many years to come.”

- Green Transportation. “Even electric vehicles, which most consumers believe are run on lithium or other battery chemistries, have a lead battery to power components like the lights, brakes, windshield wipers, airbags, seat belt pre-tensioners, the entertainment system and the heating/cooling system, among other things.” He continued, “Have you noticed when driving or renting a newer vehicle that it seems to turn off when you come to stop lights and intersections? New vehicles have a lead battery using start-stop technology, which helps reduce emissions from internal combustion engines.”

- Job Creation. Lyons believes that expanding recycling creates job opportunities for veterans and all Americans. “In the recycling industry, the three Rs – Reduce, Reuse and Recycle – offer employment in skilled and unskilled positions to manage the use of raw materials for the production of new goods. Recycling extends the life of many products … thus creating job opportunities for veterans and others in every state in the U.S. and around the world.”

- Environmental Sustainability. “With natural elements, minerals and resources diminishing, it is important that we find ways to get the most life expectancy out of a product. For those of us with a heart for the environment, it makes sense to safely recycle everything we can to make the best use of the diminishing resources we have and protect our environment for generations to come.”

East Penn Manufacturing: Founded by Air Force Veteran

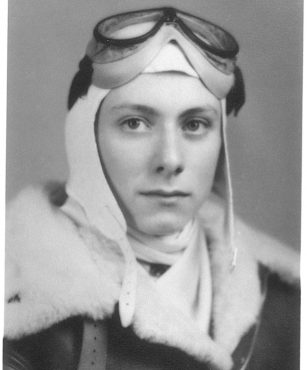

East Penn Manufacturing founder and WWII U.S. Air Force aviator, DeLight Breidegam, Jr.

East Penn Manufacturing operates the largest single-site lead battery manufacturing facility in the world. Since its earliest days recycling in a one-room battery shop in 1946, sustainability has been a core value. So has East Penn’s support for military personnel and their families.

East Penn’s founder, DeLight Breidegam, Jr., was an Air Force veteran, and he understood the need for such support. The company continues to hire veterans like Assistant Plant Manager Barry Frain.

“When I was deployed, East Penn continued to contribute to, and maintain, health insurance for me and my family. Normally, you would switch to military insurance during deployment, but East Penn’s philosophy is that when you are deployed, they don’t want you worried about what’s happening at home, but instead to focus on where you are. Leadership also checked in with my family while I was gone. It’s a support network that’s tremendous.”

East Penn Manufacturing Assistant Plant Manager Barry Frain retired from the U.S. Marine Corps after 30 years of service.

Because of its consistent support, this year East Penn received the Seven Seals Award from the ESGR (Employee Support of The Guard and Reserve). The Seven Seals Award is presented in recognition of significant individual or organizational achievement, initiative or support.

East Penn practices a deep commitment to sustainability, too, demonstrated by the company’s closed-loop approach to environmental protection. The company’s sophisticated recycling facility processes approximately 30,000 batteries per day – recycling virtually 100% of each spent battery received for processing, explained Chris Pruitt, East Penn CEO and President.

“Think about it. On a Monday, a customer sells us a battery back that’s been used. It no longer has life. By that next Monday, that battery is brand new, most of it’s all out of recycled material.” The company even reclaims sulfuric acid from spent batteries for use in new energy storage devices.

Whether it’s protecting the environment through innovative recycling or supporting the military personnel who work at its facility, honoring commitments will continue as an essential part of East Penn.

Learn More

Interstate Batteries Recycling

East Penn Manufacturing

EPA America Recycles website