ANAHEIM, Calif. — The 2025 BCI Environmental Health & Safety (EHS) Conference convened in Anaheim over September 17-18, drawing roughly 100 participants from across the U.S. battery manufacturing and recycling sector.

The bi-annual gathering is the largest dedicated forum for lead‑battery industry EHS professionals, and provided two days of educational briefings, expert panels, and peer networking focused on evolving regulatory and operational safety challenges.

“EHS is at the core of the battery industry, and Battery Council International is committed to constant improvement when it comes to the handling and processing of lead,” said BCI’s President and Executive Director Roger Miksad. “It is not an exaggeration to say that North American battery companies operate at the highest levels of health and safety in the world, and it’s critical that we have a forum for stakeholders to share best practices and stay ahead of evolving regulatory obligations.”

Regulatory pressure and practical responses

BCI’s EHS conference was focused in part on compliance with New Cal/OSHA Lead Exposure Regulations, which took effect at the beginning of 2025.

Throughout the two days, presenters underscored both the seriousness of California’s updated occupational lead-exposure rules and the urgency for companies to adapt. One presentation, for example, dissected permissible exposure limits, medical surveillance provisions, and reporting requirements under Cal/OSHA.

Attendees heard case studies from early adopters, some of whom had already begun reshaping processes in anticipation of the 2025 mandate. Presenters also stressed diligence in operations outside of California as Federal OSHA and several state OSH agencies are reviewing their lead (Pb) standards. These sessions stressed the importance of thorough hygiene practices, engineering controls, ventilation management, and worker PPE practices. Several speakers also emphasized that compliance is not a one‑time fix: it demands ongoing vigilance, documentation, and worker training.

In addition to the presentations focused on the new lead standard in California, attendees learned about best practices for work in hot environments, state trends in stationary storage permitting and standardization, the implications of PFAS use in batteries and battery components, and battery EPR laws and legislation and related litigation in Oregon state.

Another recurring theme was balancing cost pressures with safety investments. Many firms voiced concern over retrofit expenses or staffing constraints. But presenters urged that noncompliance risk—not just fines, but potential worker health liability and reputational damage—makes proactive investment both a moral and business imperative.

Peer exchange & connected learning

Beyond structured panels, much of the conference’s value lay in peer-to-peer exchange.

EHS managers from battery firms, recycling operations, and safety consulting firms compared real-world challenges: implementing air sampling protocols, interpreting ambiguous regulatory language, or upgrading facility HVAC systems under tight capital budgets.

Networking breaks also provided ample opportunity for the exchange of information, and one hallway conversations frequently turned to shared challenges and opportunities for future improvement.

A special thanks to U.S. Battery for hosting a tour

In a nod to experiential learning, the agenda also offered an optional add‑on: a behind‑the‑scenes tour of the U.S. Battery Manufacturing facility in Corona, CA.

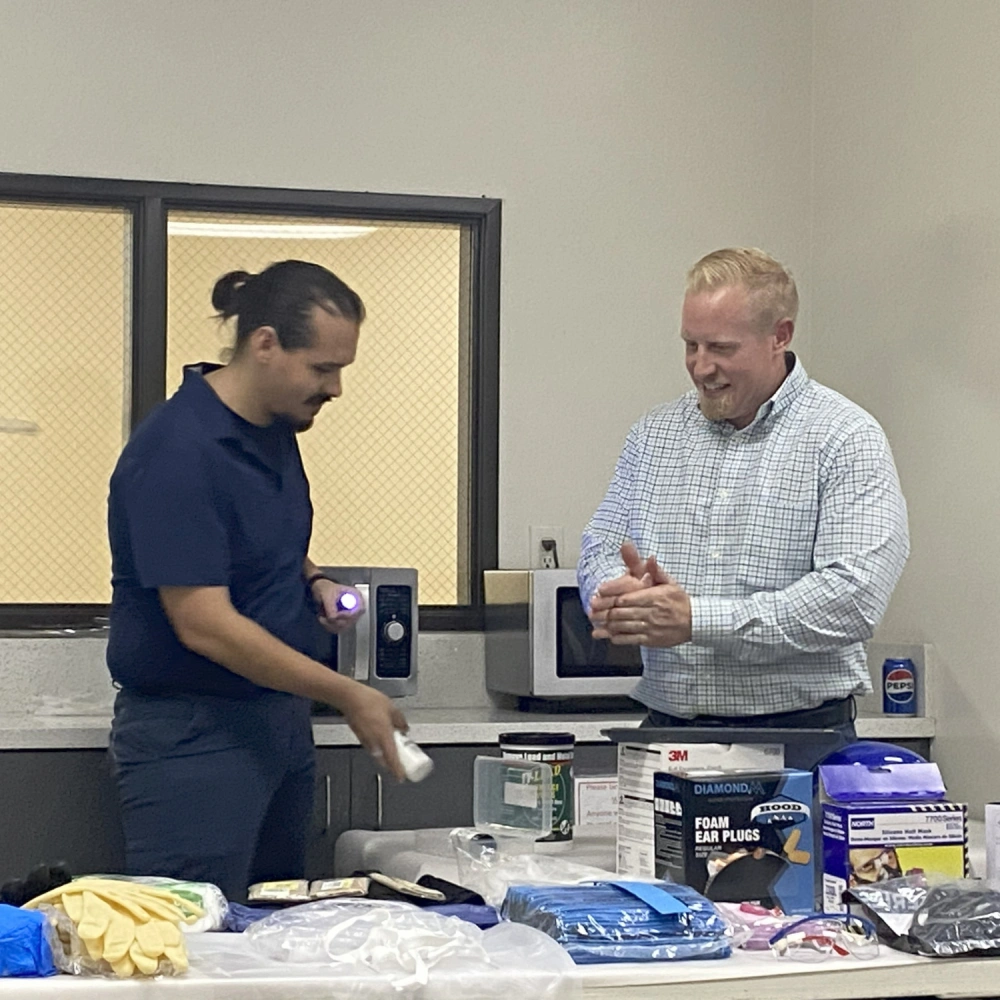

More than 50 participants took a short bus ride from Anaheim to the plant, donning safety gear and engaging with U.S. Battery staff on issues related to real-world manufacturing processes.

“It’s one thing to read about regulations on paper, but it’s very different to address them in real-world applications.,” said BCI’s Roger Miksad. “U.S. Battery’s best-in-class EHS protocols provided a tremendously valuable learning opportunity, and we’re so grateful to the team in Corona for sharing their success story with other stakeholders in the industry.”