Your Hybrid’s Lead Battery Might Appear in Your Grandkid’s Future Vehicle

Did you know that a lead battery can span generations, thanks to a 99% recycling rate? That’s because the lead in a battery can be infinitely recycled, meaning that someday the battery in your grandkid’s hybrid or EV may contain recycled lead from the car battery under your hood today.

A typical new lead battery is comprised of 80% recycled material from a spent or used lead battery, including lead, plastic and sometimes the electrolyte. That unrivaled sustainability is the message that the lead battery industry is proudly sharing on America Recycles Day, November 15, a nationally recognized program led by Keep America Beautiful.

Lead Batteries Set the Standard of Circularity Success

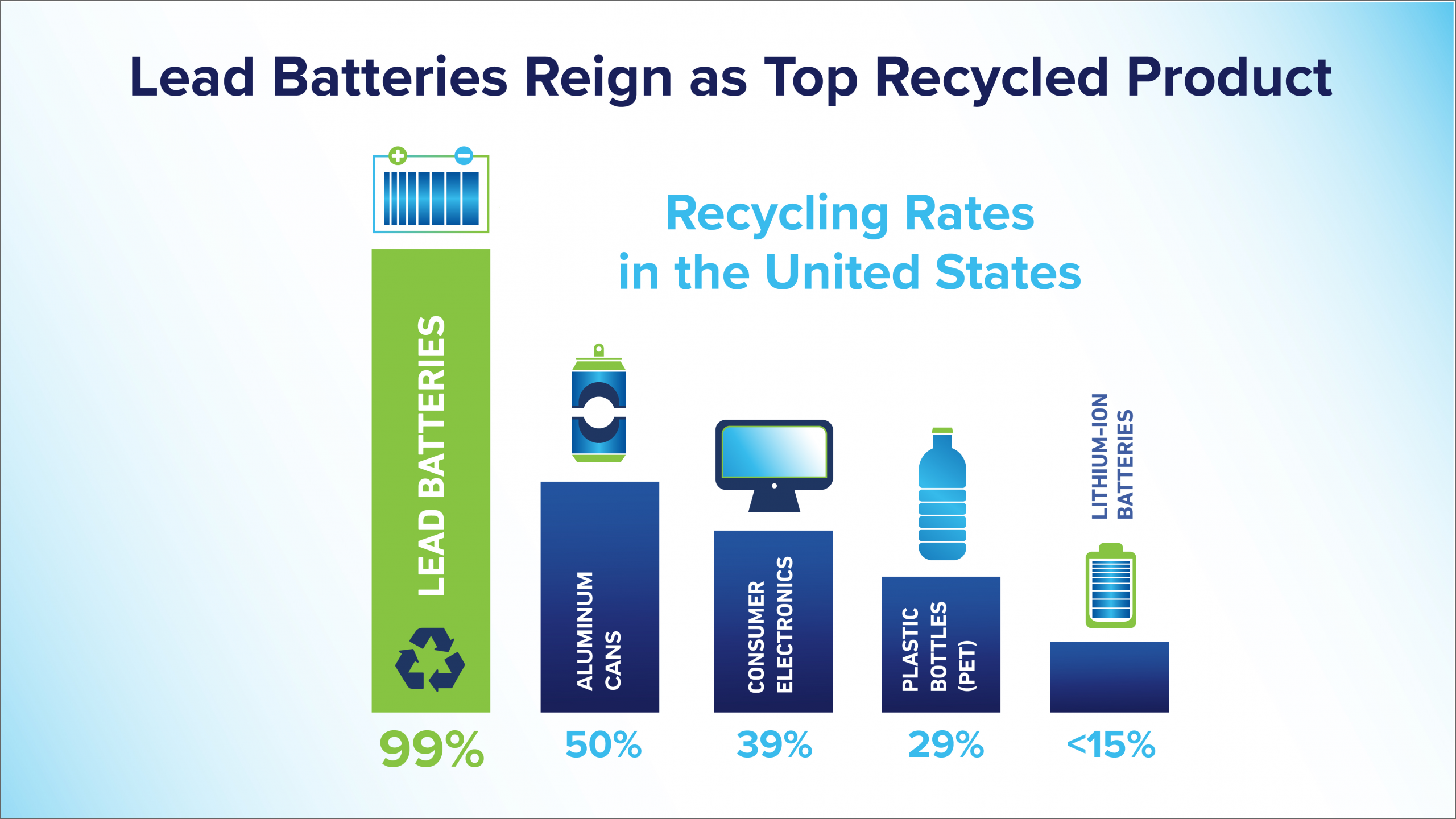

Bridging the old to new is the lead battery industry’s specialty. Lead battery manufacturers design lead batteries for recycling, making them the most recycled consumer product in America (aluminum cans are second), according to the U.S. Environmental Protection Agency. That’s made lead batteries the gold standard in how to create a highly successful, closed-loop, domestic circular economy – one where no other industry can compare.

The lead battery industry has optimized the fact that lead in lead batteries can be infinitely recycled without any loss of quality or performance. At their end of life, lead batteries are separated into three key components – all of which are 100% recyclable – lead, plastic and acid. They are then turned into the valuable raw materials U.S. manufacturers need to create new lead batteries and restart the cycle of use-recycle-remanufacture.

Lead Battery Infrastructure is Built for Sustainability

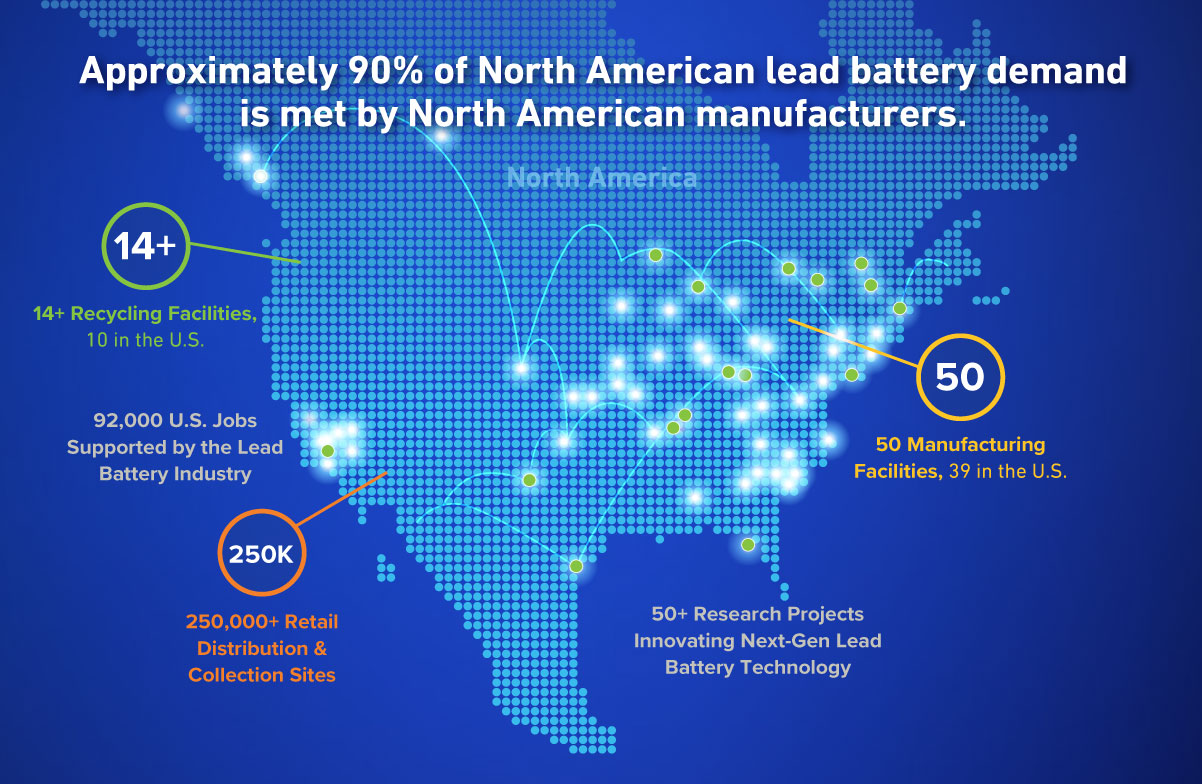

Unlike new battery chemistries, lead batteries have an established coast-to-coast network of existing manufacturing, collection and recycling facilities in North America. The industry is built for, and committed to, sustainability, which also ensures a reliable domestic supply chain for lead battery manufacturers. The system is highly efficient when supplied with a steady supply of used lead batteries. This efficiency is one of the core drivers of lead batteries’ unparalleled recycling success.

Consider data points taken from our factsheet on the North American lead battery industry’s domestic infrastructure. There are:

- 50 lead battery manufacturing facilities, 39 in the U.S.

- 14+ recycling facilities, 10 in the U.S.

- 250,000+ retail distribution and collection sites for used batteries.

Lead Batteries Provide Big Environmental, Economic and Security Benefits

The collective efforts of the lead battery industry are essential to help meet the growing need for energy, renewable energy storage, and a low-carbon future:

• Modern, closed-loop recycling in the U.S. keeps 130 million lead batteries from landfills each year and provides U.S. battery manufacturers a secure domestic supply of recycled inputs.

• Recycling lead batteries reduces mining for new raw materials and the environmental impact of doing so. Modern lead battery manufacturers today produce new lead batteries with 90% less energy and 90% fewer GHG emissions, thanks to recycling.

• U.S. lead battery manufacturers source approximately 86% of the needed lead from North American recycling facilities.

• Approximately 90% of North American lead battery product demand is met by North American manufacturers, reducing international supply chain disruptions.

• Lead batteries rank among the top five consumer product categories in sustainability.

• More than 25,000 workers build and recycle batteries in America, along with other economic contributions of the lead battery industry.

Celebrate Lead Battery’s Circularity Success on America Recycles Day

As a pioneer in sustainability, the lead battery industry has been recycling batteries for over a century. Its near perfect rate of spent battery recycling is a true recycling success story to applaud on America Recycles Day.

But equally important is how the industry leverages its recycled material. Its practices have created a model closed-loop circular economy for other industries committed to sustainable, environmentally-conscious principles to emulate.

It’s that commitment, paired with lead battery innovation, that keeps an advanced lead battery performing strong for future generations.